Fiber Bragg Gratings (FBGs) are becoming increasingly more popular for strain based SHM technique. A fiber Bragg grating is region of periodic refractive index modulation inscribed in the core of an optical fiber such that it diffracts the propagating optical signal at a specific wavelength. Bragg grating is written into a single mode optical fiber. These fibers consist of a very small diameter inner core, between 4 to 9 pm, and outer part, called cladding, having diameter of 125 pm. Due to doping by Germanium, the core has higher refraction index than the outer part, and therefore, light propagates only through the inner core [43].

A strong ultra-violet (UV) writing laser light, which is split into two equal intensity beams, later recombined on to the fiber after traversing through two different optical paths. This forms an interference pattern at the core of a photosensitive fiber and thus creating the grating in the core of the optical fiber, which acts essentially as a wavelength-selective mirror [44]. The grating reflects the light at the Bragg wavelength (kB), which can be defined asX = 2Л n (1)

B eff

where Л is the grating period and n is the effective index of the fiber core.

eff

Any change of the grating period due to strain results in changing the characteristic wavelength of the reflected spectrum. Strain is measured based on this shift of the wavelength, AX, of the reflected spectrum, which can be calculated as-

where, = mechanically caused strain, = wavelength shift, = wavelength of the reflected spectrum at unstrained condition, = gauge factor (0.78), asp = expansion co-efficient per K of the specimen, as = change of refractive index and = temperature change in K.

FBG sensors have many advantages, such as higher adaptability to composite materials, being it possible to insert the fibers into laminates with little effects upon their strength and the stiffness. Moreover, they are suitable to measure very high value of strain, are independent from interference of the electromagnetic type, and have good resistance to corrosion, high long term stability, small size and a light weight. The signal produced by FBG sensor is independent of the distance. Besides, FBG sensors are intrinsically passive, so no electrical power is needed and therefore, can be applied to high voltage and potentially explosive environments.

|

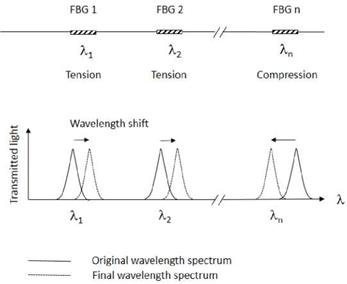

Figure 5. Multiplexing of FBG sensors. |

Another unique capability of FBG sensor is the multiplexing [45], i. e., a number of FBG sensors can be inscribed into a single optical Fiber. Each individual FBG sensor reflects back a spectrum centered in a wavelength different from one another (Figure 5), thus creating an array of strain sensors suitable to monitor large structures.

In parallel to the great advantages, FBG sensors have some features which must be taken into account while considering their application. FBG sensors show great temperature dependence which is evident in equation 2. The shift of the wavelength for 1°C is almost equal to the shift produced by an 8 pm/m strain [43]. Besides, FBG shows high sensitivity to lateral force and pressure and the stiffness of FBG sensors causes higher parallel force to the specimen. Nevertheless, in spite of these aspects, FBG is showing great potential for strain sensing due to its unique advantages.

21 декабря, 2015

21 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике