Leuco dye and coreactant are individually milled in an aqueous solution of binder such as poly(vinyl alcohol) or hydroxyethylcellulose by means of an attrition or sand mill until the particle size of the solid materials is about 1 qm or less in diameter. Smaller particles provide superior performance.

These dispersions thus obtained are mixed together, and after the introduction of other additives, coated (at about 5-10 g/m2 as dry solid) on a substrate such as paper, synthetic paper, or plastic film, dried, and calendered to give thermosensitive recording paper.

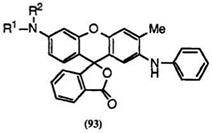

As for leuco dyes, black developing fluoran compounds are exclusively employed. They should be carefully selected to give thermosensitive recording papers of high whiteness and high image stability. Consequently, 2′-anilino-6′-di-n-butylamino-3′-methylfluoran (93; R1, R2 = n-C4H9) and 2′-anilino-6′-(A-ethyl-A-isopentylamino)-3′-methylfluoran (93; Ri = C2H5, R2 = 1-С5И11) are generally used.

|

|

on whiteness, sensitivity, and image stability of thermosensitive recording paper. All of the coreactants used in thermosensitive recording papers are phenol derivatives, and representative examples are shown in Table 10.

2,2-Bis(4-hydroxyphenyl)propane (Bisphenol A) has been most widely used, because it gives a fairly stable image and is low in price. In the past, it presented a problem for high-speed recording because of its high melting point, which has, however, been solved by using suitable sensitizers. Benzyl 4-hydroxybenzoate and 1,7-bis(4-hydroxyphenylthio)-3,5-dioxaheptane are

suitable for high-speed recording without sensitizer, but inferior to Bi — sphenol A in image stability. 4-Hydroxy-4′-isopropoxydiphenyl sulfone has received attention recently due to its image stability. 3,4-Dihydroxy-4′- methyldiphenyl sulfone is solely used in prepaid cards.

In addition to leuco dye and coreactant, many additives such as sensitizer, stabilizer, filler, lubricant, antipressure agent, etc. are used in the thermosensitive layer.

Coreactants having a higher melting point cannot provide enough image intensity on high-speed or low-energy recording. Thus, aromatic compounds having a melting point of about 100°C are employed as

|

||

sensitizer, which makes it possible to lower the developing temperature by forming a eutectic mixture, whereas thermosensitive recording papers using lower-melting coreactants such as benzyl 4-hydroxybenzoate are of high sensitivity without sensitizer. Table 11 shows representative sensitizers.

The recorded images are subject to fade on long storage or under hot humidity. To counter this, hindered phenol derivatives are employed as stabilizer. It is essential to use a stabilizer when benzyl 4-hydroxybenzoate is a coreactant. Benzyl 4-hydroxybenzoate has a high crystallization resulting in bleeding from the recorded image. Addition of stabilizer is effective in preventing such bleeding. In addition, aromatic carboxylic acid metal salts such as calcium benzyl phthalate are effective stabilizers for plasticizer and oil. Table 12 shows typical stabilizers.

White pigments such as calcium carbonate, aluminum hydroxide, silica, kaolin, or urea-formaldehyde resin are used as filler. The filler functions as an absorbent of melted components to prevent their adhesion on the thermal head. Thus, the filler is required to be high in oil absorption and not to wear the thermal head.

Metallic soaps such as zinc stearate or calcium stearate are used as lubricant, which reduces the friction coefficient of the surface of the thermosensitive layer resulting in smooth running on recording machines.

Ref.

83

83

84

85

86

The smoothness of the surface of the thermosensitive layer has considerable influence on image intensity and image reproducibility. This is achieved by calendering of high line pressure. So, paraffin waxes are used as antipressure agent in order to prevent undesirable coloring on calendering.

10 сентября, 2015

10 сентября, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике