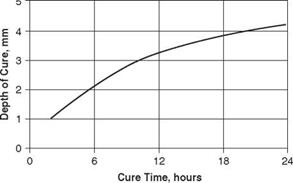

Single-component silicone adhesives are usually RTV based and so cure slowly in the presence of atmospheric moisture. The RTV will release a by-product during the cure cycle and the most common of these is acetic acid. These ‘acetoxy’ curing silicones will skin over in about 15-20 minutes and achieve a full depth of cure of 4-6 mm over 24-48 hours depending on the % RH at the time of cure (Figure 1.28).

|

Figure 1.28 Cure speed curve for an RTV acetoxy silicone (50% RH, 23 °C) |

The acetic acid by-product can be corrosive, particularly to copper terminals on printed circuit boards and other electrical items. For this reason other RTV silicone sealants have been developed with oxime — or alkoxy-based by-products. These can be slightly slower to cure than the acetoxy-based products but often the adhesion to plastics is considerably improved.

Two-component systems can also be formulated with no by-products and which cure very quickly.

One of the main benefits of silicone technology is its outstanding temperature resistance (typically >250 °C) but a disadvantage is that the products cannot be over-painted after cure. In many industrial premises where there is a paint shop, RTV silicones are prohibited due to the contamination from the by-products.

10 сентября, 2015

10 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике