Semi-crystalline polymers are plastics that contain areas of both crystalline molecular structure and amorphous regions as well (Figure 2.3). The degree of crystallisation depends on the chemical structure (generic type), the rate of cooling and the thermal history in the post-moulded state. Very rapid cooling in thin sections can result in insignificant levels of crystallisation and this is used to great effect in the production of transparent film (e. g., polyethylene (PE), polyethylene terephthalate and polypropylene (PP)).

Increased crystallisation increases and improves hardness, modulus, strength, abrasion resistance, shrinkage, density and opacity.

Semi-crystalline thermoplastics are generally used in applications where high fatigue resistance or repeated cyclic loading is involved (bearings, linkages, etc.). They are often reinforced with glass fibres and this considerably improves the high-temperature stiffness and the strength. However, the shrinkage can be variable and difficult to predict. Semi-crystalline thermoplastics are noted for very good electrical properties as well as the ability to withstand both high heat and severe chemical environments. Examples of semi-crystalline thermoplastics include polyamide, polyarylamide, LCP and PBT [1].

|

Figure 2.3 Semi-crystalline plastic |

The amorphous thermoplastics are generally easier to adhesively bond than the semicrystalline thermoplastics, although some nylons will bond quite well (Table 2.1).

|

Table 2.1 Some examples of amorphous and semi-crystalline thermoplastics |

|

|

Amorphous |

Semi-crystalline |

|

Polyphenylene oxide (PPO) (Noryl) |

Polyetheretherketone (PEEK) |

|

PC |

Polytetrafluoroethylene (PTFE) |

|

Polyethersulfone (PES) |

PBT |

|

PS |

Polyamide (PA) |

|

Polysulfone (PUS) |

PPS |

|

Polyamide (amorphous) (Nylon) |

Polyethylene terephthalate (PET) |

|

PMMA, Acrylic |

Polyoxymethylene (POM) (Acetal) |

|

PVC |

PP |

|

ABS |

PE |

|

Ionomers |

LCP |

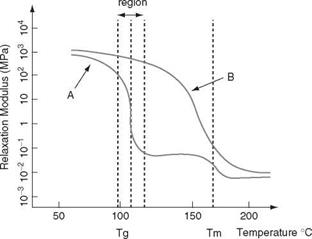

The glass transition temperature (Tg) is an important property of thermoplastics and is the temperature at which the plastic will change in its mechanical properties (depending on the degree of crystallinity) due to the onset of the breakdown of the physical bonds within its structure (see Figure 2.4). The glass transition

|

Glass transition

Figure 2.4 Influence of temperature on relaxation modulus for thermoplastics ((A) amorphous, and (B) semi-crystalline) |

temperature is not a sharp temperature point but the average value of the transition range.

Thermoplastics are elastic and flexible above a glass transition temperature Tg, specific for each one, and in some cases a low Tg is useful and in other applications a high Tg is required. A polyethylene ice box container has a very low Tg as it is essential that it remains flexible at temperatures below -20 °C. A blood filter must retain all of its structural integrity at temperatures >37 °C and therefore polycarbonate is often the selected plastic as it has a high Tg (amongst other properties).

18 сентября, 2015

18 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике