5.3.1.1

Introduction

Special effect pigments, which can be natural or synthetic, show outstanding qualities of luster, brilliance and iridescent color effects based upon optically thin layers [5.1225.125]. This visual impression develops by reflection and scattering of light on thin multiple layers. In nature this is not limited to pearls and mussel shells alone; there are a multitude of birds, fish, precious stones and minerals, even insects, that

demonstrate a luster effect. Experiments to understand the optical principles of natural pearl luster demonstrate that the brilliant colors are based upon structured biopolymers and upon layered structures, which are developed by biomineralization.

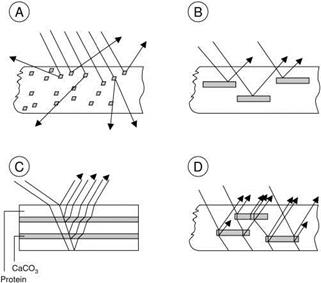

Figure 5.15 illustrates the various optical principles of conventional pigments (A) (absorption pigments), metal effect pigments (B), and pearls (C) and pearl luster pigments (D), the most important group of special effect pigments. In the case of absorption pigments, the interaction with light is based upon absorption and/or diffuse scattering. A completely different optical behavior can be observed with the group of effect pigments including pearl luster and metal effect pigments. Metal effect pigments consist of small metal platelets (for example aluminum, titanium, copper), which operate like little mirrors and almost completely reflect the incident light.

|

Fig. 5.15 Optical properties of absorption pigments, effect pigments and natural pearls. A) conventional pigment; B) metal effect pigment; C) natural pearl; D) pearl luster pigment. |

Pearl luster pigments simulate the luster of natural pearls. They consist of alternating transparent layers with differing refractive indices. The layers consist of CaCO3 (high refractive index) and proteins (low refractive index).

This difference in refractive indices, arising equally on the interface between an air/oil film or oil film/water, is a prerequisite for the well-known iridescent color images in these media. Small highly refractive platelets of pearl luster pigments align themselves parallel in optically thin systems such as paints, printing inks, or plastics. Interference effects develop when the distances of the various layers or the thicknesses of the platelets have the right values.

Synthetic pearl luster pigments are either transparent or light-absorbing plateletshaped crystals. They can be monocrystalline, as in Pb(OH)2 • 2 PbCO3 and BiOCl, or

possess a multi-layered structure in which the layers have differing refractive indices and light absorption properties.

The use of pearls and nacreous shells for decorative purposes goes back to ancient times (e. g., in Chinese wood intarsia). The history of pearl pigments dates back to 1656, when French rosary maker Jaquin isolated a silky lustrous suspension from fish scales (pearl essence) and applied this to small beads to create artificial pearls. It took more than 250 years to isolate the pearl essence material (guanine platelets) and understand the pearl effect. Attempts were made to create synthetic pearl colors as organic or inorganic, transparent, highly refractive coatings and pearl pigments as crystalline platelets. From 1920 onwards, hydroxides, halides, phosphates, carbonates, and arsenates of zinc, calcium, barium, mercury, bismuth, lead, and other cations were produced for this purpose. Only the traditional natural pearl essence, basic lead carbonate and bismuth oxychloride, is still of importance.

The strong demand for pearl effects came from the growing coatings and plastics industries, which wanted to improve the acceptance and popularity oftheir products. Furthermore, pearl luster pigments also allowed artists and designers to create new visual effects similar to those found in nature. The breakthrough for pearl luster pigments came with the invention of mica coated with metal oxides. Mica-based pearl luster pigments now account for >90% of the world market. Important manufacturers of pearl luster pigments are Merck KGaA, Germany (with overseas subsidiaries EMD Chemicals Inc., USA and Merck Ltd., Japan) and Engelhard Corp., USA.

Pearl luster pigments are used to obtain pearl, iridescent (rainbow), or metallic effects, and in transparent color formulations to obtain brilliance or two-tone color, luster flops, and color travel effects (changing with viewing angle). The most important applications are plastics, industrial coatings, printing inks, cosmetics, and automotive paints.

Table 5.13 shows an overview of inorganic pigments with luster effects. Effect pigments can be classified with regard to their composition as metal platelets, oxide — coated metal platelets, oxide-coated mica platelets, oxide-coated silica, alumina and borosilicate flakes, platelet-like monocrystals, comminuted PVD films (PVD = physical vapor deposition), and liquid crystal polymer platelets (LCP-pigments, the only industrially relevant organic effect pigment type) [5.124-5.126]. The aims of new developments are new effects and colors, improvement of hiding power, more intense interference colors, increased light and weather stability, and improved dispersibility. Of special interest are pigments which are toxicologically safe and which can be produced by ecologically acceptable processes.

The total market for effect pigments can be estimated to be about 50,000 tons per year. Half of this amount can be calculated to be special effect pigments, the other half to be metal effect pigments.

5.3.1.2

3 января, 2016

3 января, 2016  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике