The feasibility of using adhesives, in combination with bolts, to bond common structural details on highway bridges has been examined carefully by Albrecht et al.(16-18). The motives behind their work were to (a) increase the fatigue strength of steel bridge members, (b) reduce the connection size without lowering the fatigue strength, and (c) eliminate welded details with low fatigue strength. A structural acrylic adhesive was selected for the tests described below(17); surface treatment involved shot-blasting.

|

A number of tension splices using various combinations of bolting, fabricated with and without adhesive bonding, were fatigue loaded (Fig. 8.12). The results showed that bonding, in addition to bolting, consistently increased the fatigue life of the joints, offering the potential to reduce the number of bolts to develop a specified mean fatigue strength.

![]() c

c

Fig. 8.12. One — and two-bolt tension splices (Ref. 17).

285

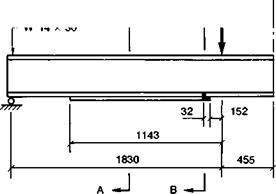

Several beam specimens were fabricated consisting of rolled beams whose flanges and webs were spliced at mid-span (Fig. 8.13). The beams were tested in four-point bending, with the splice located in the region of constant bending moment. The flanges were spliced with plates of different sizes, and carried the moment. The undersized web splices were provided for ease of specimen fabrication and carried no shear. Bolting, with and without bonding, was employed. Again the results showed that bonding, in addition to bolting, increases the fatigue life of the detail, offering the potential to reduce the number of bolts in order to develop a specified mean strength.

Some rolled beams were additionally fabricated with cover plates bonded to the tension flange (Fig. 8.14). The original intention was to use adhesives only to join the cover plate to the flange, but preliminary fatigue studies indicated debonding of the plate-ends. High strength bolts were therefore introduced to negate the tendency towards peeling. When this was done, the fatigue life was increased by a factor of 20 over that of conventionally welded cover plates.

г

г

L — 171 x 13 x 1143 plate

Fig. 8.13. Four- and six-bolt beam splices (Ref. 17). 286

Symmetrical about <£ В -—і P/2

A-A B-B

Fig. 8.14. Cover-plated beam specimen (Ref. 18).

The study concluded that the largest increase in the fatigue strength of structural steel details was obtained by replacing welded connections with bonded and bolted connections. When properly detailed, such connections would be virtually fatigue-proof for highway bridge loading. However, it would be desirable to find adhesives with superior creep resistance and durability to cope with the expected service life.

Hollow sections and truss connections

Joints between, and attachments to, rolled hollow sections would seem to provide opportunities for adhesive bonding. For instance,

the attachment of handrails to pedestrian overbridges constructed from hollow sections such as vierendeel girders, or the fabrication of gusseted or socketed nodes and joints between members. The use of adhesives would also provide an effective seal to the hollow sections. Similarly, adhesives could be used to fabricate suitably designed joints in trusses comprising various structural sections.

22 сентября, 2015

22 сентября, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике