A potential structural application of epoxy resin adhesives in bridge construction is to use them to form the necessary shear connection between steel girders and the concrete deck slab in composite bridges, in place of conventional welded mechanical fasteners. There are three ways in which bonded shear connections between steel and concrete might be achieved.

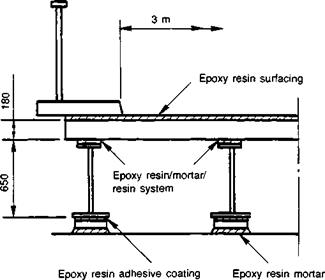

Post-bonding. Adhesives may be used to bond precast concrete slab units directly to the steel surface. Such a technique has been successfully employed in Germany(8). On one bridge epoxy resins were used in a variety of forms and locations on the superstructure (see Fig. 7.8). This included rubber bearings bedded in epoxy mortar and an epoxy adhesive coating between the main steel girders and the bearings. Of most interest structurally, however, is the use of epoxy resin adhesive mortar between the precast concrete deck panels and the main girders. The intention was to create a monolithic structure having the same degree of strength and composite action as might be expected with conventional jointing methods. Four

|

Fig. 7.8. German bonded bridge (Ref. 8). 254 |

years after construction the bridge was subjected to full scale load tests and the resulting deflections compared with those based on full and zero composite action. In both the load cases considered, actual deflections were never more than those calculated assuming full effective bonding and were four to five times less than in the unbonded case. It is also worth mentioning that such results were obtained after a period in which the river being bridged rose to the level of the superstructure on three occasions and, in one case, completely submerged the entire structure. It is reported that subsequent visual monitoring has revealed the joint edges to be free of cracks or other damage. The final use of adhesives in this structure was in the form of an epoxy adhesive surfacing on the precast concrete deck panels which was also employed to seat the precast concrete kerb units.

Grip layer. A layer of coarse aggregate may be bonded to the steel to form a rough layer onto which fresh concrete is subsequently poured. This technique has been the subject of some research involving slab panels, tensile reinforcement being provided in the form of a thin soffit steel plate. However, premature adhesive failures have been reported and an improved bonding technique is considered to be necessary(9).

Pre-bonding. Fresh concrete is poured directly onto a layer of uncured adhesive spread over the prepared steel surface. This method, as used in the reinforcement of slab units by externally bonded plates, has been the subject of extensive research by the Wolfson Bridge Research Unit(10). ‘Open sandwich’ slabs, based on either a flat soffit plate or a plate curved slightly upwards to form a shallow arch have been recommended. The technique is described in some detail in Chapter 8.

3 сентября, 2015

3 сентября, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике