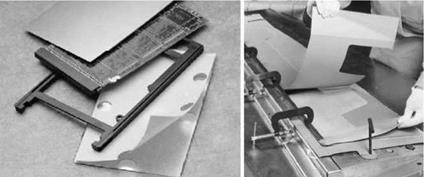

The processing of film adhesives is particularly simple, accurate and clean if die — cut shapes are used (Figure 6.26). Structural film adhesives are available as nontacky films made from modified hot-setting epoxy resins or phenolic resins, respectively.

|

Figure 6.25 Spraying of hot-melt adhesive. (Photo courtesy of Ellsworth Adhesives). |

|

Figure 6.26 Application of die-cut film adhesives. (Photo courtesy Ellsworth Adhesives). |

In order to prevent bonding faults, the adherents must be pressed thoroughly against each other. Compressed air cushions or vacuum foil bags are used for large — size adherents.

PSAs are physically setting systems and generally do not require any curing process. Common PSAs are permanently tacky, and are mostly processed in the form of converted adhesive tapes. Automatic application devices are available for industrial manufacture purposes.

Die-cut films (Figure 6.27) are particularly well suited for large surface bonding and lamination purposes. It is possible to create either permanent or detachable joints according to the properties of the different types of adhesive.

10 октября, 2015

10 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике