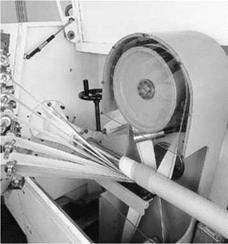

Tissue paper is commonly wound onto cores (board rolls) made from strips of paperboard wound on a horizontal spindle while simultaneously being bonded layer to layer; the result is a continuous core that is then cut to the desired length (Figure 8.37).

The paperboard has a basic weight of 120-160 gm-2, with two to four (or more) layers being commonly bonded to each other. The winding speeds can reach 140 m of core per minute. Core winding adhesives are often based on dextrin with a solids content of 35-50%, or on polyvinyl acetate homopolymers. In some special cases, animal glue is also employed. The adhesives must provide secure, rapid bonding of the paper strips, allowing the wound cores to be very accurately (tolerance ± 2 mm) cut immediately after manufacture. As the cores must be mechanically stable, the adhesives must contribute towards the stiffness of the core.

Polyvinyl acetate homopolymer-derived adhesives are used for machines running at more than 60-80 m min-1. They have premium adhesion properties, even on difficult papers, and can easily be redispersed during the recycling process. Although adhesives derived from dextrin (usually applied at 50 °C) also confer the desired properties to the cores, their slow setting process is a limiting factor for winding speed. When using dextrin for core winding, it is important to know that, during the recycling of the paper, the pulp will contain adhesives and auxiliary products such as borate that are commonly added to dextrin adhesives to increase the setting rate. The borate may react with polyvinyl alcohol from other sources (e. g. lamination) and

|

|

cause flocculation that may give rise to problems during recycling (e. g. so-called ‘fisheyes’). Polyvinyl acetate homopolymer-derived adhesives are always supplied as ready-to-use products, whereas dextrin-based adhesives may be ready for use or supplied as dry powders that are mixed with water prior to use. When using dry dextrin, care must be taken to use the correct mixing ratio in order to ensure the correct viscosity, processing properties and setting speed. Core-winding adhesives are applied to the paperboard either by means of roller or nozzle applicators.

3 декабря, 2015

3 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике