From the two studies discussed above, it is clear that, in order to measure the entire profile of BFS along the backface of the bonded region, the use of an array of strain sensors is a feasible solution.

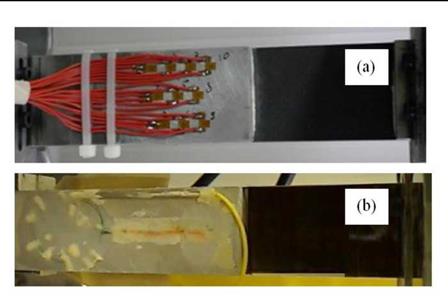

It is also seen that, the use of an array of FBG sensors yields more accurate results compared to that of strain gages, presumably due to the fact that array of FBG is much more compact (Figure 11), allowing to place all the sensors along the centerline of the specimen, thus minimizing the effect of any possible misalignment. Besides, this array of FBG sensors require less wiring (basically only the fiber containing the array of sensors). Therefore, for BFS technique for SHM purposes, an array of FBG sensors is more suitable, provided that feasible solutions are adopted for compensating the effect of temperature variations.

|

Figure 11. Visual comparison between (a) arrays of strain gauges and (b) an array of FBG sensors. |

Adhesively bonded composite joints are used in various industrial applications. The integrity of the adhesive bond mainly depends on the quality of the interface between the adhesive and the substrate as well as the ability of the adhesive to sustain the applied loads during service life. Monitoring of structural integrity is of fundamental importance for such structures. By in-situ SHM methodologies, continuous real time monitoring might reduce maintenance costs while also increasing safety and reliability. Early detection of damage by using SHM techniques might also allow for extending the life of the structures, based on a damage tolerant design philosophy.

The BSF technique employing an array of sensors is one of the methods allowing for the detection of the initiation damage and continuous monitoring of fatigue cracks under service loads, at least for certain joint configurations, like the SLJ. Although both conventional electrical resistance strain gauges and optical FBG sensors can be used to construct array of strain sensors to detect BFS distribution for monitoring purposes, optical FBG offer many advantages in terms of compactness and ease of installation.

The authors gratefully acknowledge the contributions of Dr. Lorenzo Comolli, Dipartimento di Meccanica, Politecnico di Milano, to the development of the case studies discussed in this chapter.

2 января, 2016

2 января, 2016  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике