Typical formulations for wood finishes are given below :

(i) Water Based Self-Crosslinking Basecoat

|

self crosslinking acrylic[12] |

86.00 |

|

demineralised water |

3.00 |

|

Dehydran 1293 |

0.50 |

|

Byk-344 |

0.20 |

|

Dapro W-77 |

0.50 |

|

Coatex BR 125 |

0.20 |

|

silica matting agent |

0.90 |

|

butoxy propanol |

5.00 |

|

propylene glycol |

0.50 |

|

demineralised water |

2.00 |

|

AMP-95 |

0.10 |

|

Mergal K6N |

0.10 |

|

Polymul ms 40 |

1.00 |

|

Total |

100.00 |

Sheen

Viscosity

pH

SG

Solids

60-70%

40-45 secs B4 @ 20°C

8.0- 9.0

1.05

37.8%

The matting agent is dispersed in the acrylic emulsion. A defoamer, Dehydran 1293 (Henkel), and a slip/flow aid, Byk 344 (Byk Chemie), are added at the dispersion stage. Dapro W-77 (Daniel) is a polyurethane thickener. Coatex BR 125 (Coatex) improves wetting. Butoxy propanol and propylene glycol help with the coalescence of the film. AMP-95 adjusts the pH. Mergal K6N (Hoechst) is a fungicide. Polymul MS 40 is a wax dispersion to improve mar resistance.

(ii) A Self-Crosslinking Satin Lacquer

|

butoxy propanol |

5.00 |

|

silica matting agent |

0.80 |

|

Coatex BR 125 |

0.80 |

|

demineralised water |

12.10 |

|

AMP-95 |

0.10 |

|

Byk-344 |

0.50 |

|

Dehydran 1293 |

1.00 |

|

paint additive DC 51 |

0.20 |

|

Dapro w-77 |

0.50 |

|

propylene glycol |

2.30 |

|

Mergal K6N |

0.10 |

|

Jonwax 35 |

6.00 |

|

self-crosslinking acrylic emulsion1 |

70.60 |

|

Total |

100.00 |

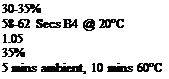

Sheen

Sheen

Viscosity

SG

Solids

Drying

1 42% solids emulsion

Stir the silica matting agent in butoxy propanol and the viscosity modifier until fully dispersed. Then add other additives and polymer. Dehydran 1293 should be mixed until a crater-free film is obtained on glass. DC 51 (Dow Coming) is a wax for improved slip. Jonwax 35 (Johnson) improves mar and adjusts the sheen. Propylene glycol is used as a coalescent and plasticiser.

|

acrylic emulsion (42% in water) |

68.00 |

|

hard acrylic emulsion(40% in water) |

9.25 |

|

demineralised water |

10.00 |

|

Neocryl AP-2650 |

0.13 |

|

amp 95 |

0.30 |

|

butoxy propoxy propanol |

4.00 |

|

propylene glycol |

2.60 |

|

Aerosol ОТ 75 |

0.20 |

|

Polymul MS 40 |

2.30 |

|

fungicide |

0.10 |

|

AMP-95 |

0.30 |

|

demineralised water |

2.82 |

|

Total |

100.00 |

|

FORMULATION 7-3 |

85% +

85% +

38 — 42 secs b4 @ 20°C

8.0- 9.0

1.03

37.1%

A blend of hard and soft acrylics is used to give a balance of MFFT and properties. The hard polymer is non-film forming at room temperature and imparts excellent block resistance. Examples of hard acrylics would be Rhoplex WL-91 (Rohm & Haas) with a Tg of 52°C and Joncryl 89 (Johnson) with a Tg of >80°C. The soft polymer is a room temperature film forming resin with good adhesion, gloss and water resistance. Examples of soft acrylics would be Rhoplex B-15 (Rohm & Haas) with a Tg of <0°C and Joncryl 77 (Johnson) with a Tg of 20°C. Increasing the amount of hard polymer gives harder, more block resistant films. However, this will increase the MFFT and may require additional coalescent to ensure good film formation. The use of slower evaporating solvents is recommended when using high levels of harder copolymer or in ambient drying situations where high humidity may be present.

Water, defoamer (Neocryl AP-2650, Zeneca), pH adjuster (AMP 95), coalescents, and surfactant (Aerosol ОТ 75) are added and thoroughly mixed for 20 minutes. A wax dispersion, for improved mar resistance, and fungicide are then added. Final pH adjustment is with AMP 95, and viscosity with demineralised water.

(iv) A Spray Applied White Primer

|

Millbase |

|

|

demineralised water |

6.40 |

|

Mergal К 6 N |

0.20 |

|

AMP 95 |

0.40 |

|

dibutyl phthalate |

1.30 |

|

Texanol |

4.00 |

|

Orotan 731 25% |

0.60 |

|

magnesium carbonate |

11.30 |

|

titanium dioxide |

4.50 |

|

talc |

3.60 |

|

Let down |

|

|

demineralised water |

8.50 |

|

acrylic emulsion (42%) |

44.60 |

|

hard acrylic emulsion (40%) |

10.60 |

|

Tego foamex 1488 |

0.40 |

|

Coatex BR125 |

0.60 |

|

demineralised water |

3.00 |

|

Total |

100.00 |

|

FORMULATION 7-4 |

1.4 -1.6 Poises Rotothinner @ 20°C

1.4 -1.6 Poises Rotothinner @ 20°C

1.18

44.7%

10-12 minutes @ 60°C

Premix and disperse the ingredients in the millbase to 30 microns. Then let down with the polymers, water and defoamer. Orotan 731 (Rohm & Haas) is used to disperse the millbase. Dibutyl phthalate is a plasticiser. Texanol helps coalescence. Magnesium carbonate and talc are cheap extenders used with the titanium dioxide pigment, with levels used depending on hiding power required. The combination of platy talc and amorphous silica is recommended for exterior applications. Viscosity is adjusted with Coatex BR125 and water.

(v) White Roller Coating Basecoat

|

FORMULATION 7-5

|

Properties

Viscosity 5.0-5.5 Poises Rotothinner @ 20°C

pH 8.0-9.0

SG 1.40

nvc 55.9%

Premix the first seven components and add titanium dioxide and magnesium carbonate whilst stirring. Then high speed disperse to Hegman 6+. Joncryl 8086 is a dispersing resin from S C Johnson. Orotan 731 is a dispersing agent from Rohm & Haas. Tego foamex 1488 reduces foaming in dispersion. Ammonia is used to adjust the pH. Mergal K6N (Hoechst) is a fungicide.

When fully dispersed, add the let-down mixture. Allow to mix well, with cooling if necessary. Adjust the final viscosity with premixed Borchigel L75 (Borchers) and demineralised water.

(vi) Spray Applied Satin White Lacquer

|

acrylic emulsion (42% in water) |

60.00 |

|

hard acrylic emulsion(40% in water) |

8.00 |

|

demineralised water |

7.70 |

|

Neocryl AP-2650 |

0.10 |

|

AMP-95 |

0.40 |

|

dibutyl phthalate |

0.50 |

|

butoxy propanol |

5.50 |

|

Aerosol ОТ 75 |

0.20 |

|

Millbase |

|

|

demineralised water |

1.50 |

|

Orotan 731 25% |

0.05 |

|

Joncryl 8086 |

1.80 |

|

AMP 95 |

0.05 |

|

titanium dioxide |

10.50 |

|

silica matting agent |

1.60 |

|

Polymul MS 40 |

2.00 |

|

Mergal К 6 N |

0.10 |

|

Total |

100.00 |

|

FORMULATION 7-6 |

85% +

85% +

48-52 secs b4 @ 20°c

8.0- 9.0 1.12 42.8%

Mix the hard and soft copolymers. Then add water, defoamer (Neocryl AP-2650), plasticiser (dibutyl phthalate), coalescent (butoxy propanol) and viscosity modifier (Aerosol ОТ 75). Adjust pH with AMP-95. Premix and disperse the millbase. Add it to the above mixture and stir thoroughly for 20 minutes. Then add the silica matting agent, wax dispersion (Polymul MS 40) and fungicide, and stir until mixed.

(vii) A Formulation for Clear Flat Furniture Finish

|

FORMULATION 7-7

|

First mix separately parts A, В and C. Then mix part A with part В and add this mixture to part C and stir, and filter. Immediately before this varnish is used, para-toluenesulphonic acid is added until the pH is less than two. This gives a pot life of approximately eight hours.

9 октября, 2015

9 октября, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике