Viscosity is the resistance to flow in a liquid and is measured in Poise. The study of viscosity is known as Rheology and this plays an important part in emulsion applications.

|

|

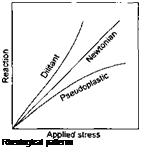

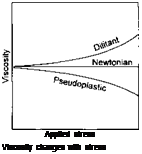

In an ideal liquid, the rate of flow is proportional to the force inducing that flow. Mobile liquids approximate to this ideal behaviour and are known as Newtonian liquids. For most commercial emulsion polymers the rate of flow increases more rapidly than the rise in inducing force. This is known as pseudoplasticity. A simple illustration of different rheological behaviour is shown in Figure 7-14.

Figure 7-14: Illustration of Rheology Definitions

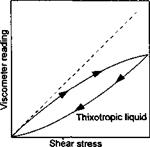

The term thixotropy has often been confused with the pseudoplastic state which is a reduction in viscosity as the rate of shear increases. Thixotropy is a reduction in viscosity with time. Almost all thixotropic liquids are also pseudoplastic, but not all pseudoplastic liquids are thixotropic. Both pseudoplastic and thixotropic behaviour are caused by ‘structure’ which involves the interactions between particles in the liquid. The strength of these interactions, and the rate at which they form, controls the rheology of the system. Viscosity measurement is not an instantaneous process and the rate of formation of interactions relative to the time of measurement determines the rheology. If interactions are formed relatively fast an equilibrium will be set up between formation (constant) and destruction (rate dependent on shear) of interactions, and the system will appear to be pseudoplastic. If interactions are formed slowly the apparent viscosity will decrease, this is because the viscometer will record a value before equilibrium is reached. In a brushing paint, the removal of brush marks requires a slow rate of forming structure. If the paint is applied to a vertical surface a fast build-up of structure is required to prevent flow of the paint down the surface, a phenomenon termed ‘sagging’.

|

|

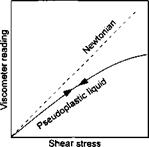

A commonly used viscometer is the Brookfield in which the resistance of a spindle rotating at a fixed speed in the emulsion is recorded. The scale reading is multiplied by a factor dependent on the spindle and its speed. The Brookfield is a cheap and reliable quality control instrument, but it is limited to a small range of shear rates from 5 to 100 rpm, so that it gives little information on the emulsion rheology. The Ferranti-Shirley viscometer measures the reaction on one plate of another (an inverted cone with a small angle making it nearly flat, different cone sizes are available) whose speed of rotation is varied from zero to a large value and then reduced. Typical Ferranti-Shirley plots are shown in Figure 7-15. Since the Ferranti-Shirley viscometer became available there has been a multitude of viscometers and many are more advanced. Contact equipment suppliers for details of more recent ranges of shear viscometers.

Figure 7-15: Ferranti-Shirley Plots of Rheology

25 сентября, 2015

25 сентября, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике