Dr. Manfred Schonfelder^ illustrated the effects of polyurethane finishes on the mechanical properties of the plastic. The abstract describes the propagation of a crack from the coating through to the plastic substrate.

The formation and growth of cracks can be impeded and hence the damage to the component restricted, by a variety of methods:

a) Adjusting the flexibility of the coating.

b) Utilising a highly elastic primer prevents crack propagation.

c) Improving the topcoats resistance to weathering.

Ideally the flexibility of the substrate and polymer should be matched e. g. RIM (reaction injection moulded) polyurethane requires a more flexible system than ABS (acrylonitrile-butadiene-styrene).

As a one coat finish for plastics, acrylic urethanes have one major limitation, the aggressive solvent content of the acrylic and the polyisocyanate resins themselves. This limits their use to coatings for thermosetting substrates and a small number of TPA substrates such as ABS, PA (polyamide), RIM polyurethane and PPO (polyphenylene oxide). Even then, the system should be evaluated to ensure that no degradation of the plastic’s impact resistance has taken place. Consult the TPA chapter for discussion on plastic substrates.

Acrylic urethanes are used widely in the coating of plastic components, primarily as a clear or pigmented topcoat for basecoated or primed plastics. Clearcoats are formulated with aliphatic polyisocyanates. The addition of a UV absorber and a hindered amine light stabiliser further improve the photostability. Catalysts for the reaction fall into two categories, namely metallic salts and tertiary amines.

|

Panels assessed for hard dry time in hours Coating system potlife 4 hours |

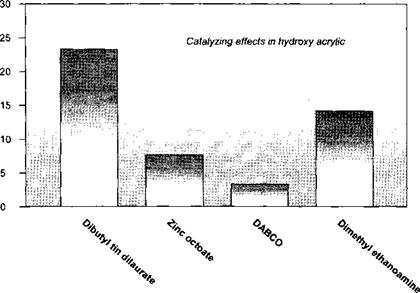

Figure 5-4

Comparison of Four Catalysts7

Panels assessed for hard dry time in hours. Coating system pot life 4 hours.

Dibutyl tin dilaurate is the most commonly used catalyst for the polyurethane reaction.

The tertiary amines have greater effectiveness, as shown in Figure 5-4, but they can have a detrimental effect on the physical properties of the coating system. A wide range of coating flexibility is possible using acrylic polyols of differing functionality and degree of polyol branching, but in general the acrylic polyols are modified with linear polyesters, e. g. Desmophen 670, for fully flexible clear coats.

Acrylic urethanes can also be modified with cellulosics, such as cellulose nitrate or CAB. The introduction of a lacquer drying component will speed up the tack free time of the system. They also extend the coating, reducing the solids at application viscosity and assist with the control of gloss in semi-matt systems.

Suitable resins for the formulation of acrylic urethane plastic coatings include :

|

Crodaplast AC-567XP |

Croda |

|

Crodaplast AC-569XP |

Croda |

|

Macrynal SM510 |

Hoechst |

|

Macrynal SM515 |

Hoechst |

|

Synocure 867SD |

CVP |

|

Synocure 865SD |

CVP |

|

Desmophen A360 |

Bayer |

TWO PACK POLYURETHANE FOR COATING PLASTICS

|

PART A |

|

|

Macrynal SM510 |

68.00 |

|

Byk 300 |

0.10 |

|

Dibutyl tin dilaurate (5%) |

0.05 |

|

Tinuvin 292 |

2.00 |

|

Tinuvin 1100 |

1.00 |

|

MIBK |

9.00 |

|

Butyl Acetate |

10.85 |

|

Xylene |

9.00 |

|

Total |

100.00 |

|

PART В |

|

|

MIBK |

24.42 |

|

Xylene |

24.42 |

|

Additive TI |

0.75 |

|

Desmodur N75 |

50.41 |

|

Total |

100.00 |

Mixing ratio of A:B is 4:1 by volume. Thin with up to 20 % butyl acetate if required.

Macrynal SM510 is 60 %nvc in 2:1:1 xylol: solvesso 100: butyl acetate with an hydroxyl content of 4.5 %. Addition of additive TI (tosyl isocyanate) is a water scavenger which helps to extend the shelf life of part B.

5 сентября, 2015

5 сентября, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике