This is governed largely by the ultimate application of the paint and so is more under the control of the paint formulator than the resin formulator. Single coat whites are, for example, usually cured with a melamine or other amino resin. The melamine resin has to be suitable for this particular use, and a number have been developed by the manufacturers especially for this use. They are all substantially fully etherified (to provide the necessary bath stability) and they are partly etherified with ethanol or butanol, to give the necessary water insolubility. They are, in essence, derivatives of hexamethoxy methyl melamine with some of the methyl ether groups replaced by the higher alcohols. Like hexamethoxymethyl melamine they are supplied substantially solvent-free because, as explained above, organic solvents in the bath can adversely affect the film resistance and hence the film quality and the rupture voltage. The hexamethoxymethyl ester itself is water soluble and hence tends to deposit at a lower ratio in the film than in the bath. (It can, in practice, be used quite successfully provided that allowance is made for this when running the bath). Typical melamine resins structures are shown in Figure 2-16.

![]()

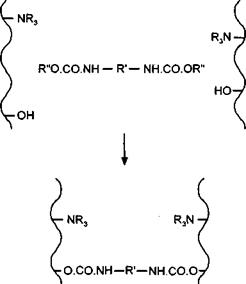

Cathodic systems are therefore cured mainly by using a blocked isocyanate although other mechanisms have been developed to get round the many patents held in this field by PPG industries. Some typical isocyanate curing reactions are shown in Figure 2-17.

|

Crosslinking

+

2R"OH

Figure 2-17

Blocked Isocyanates which can be Used as Crosslinkers in Electrodeposition Paints

All of these curing mechanisms require the presence of hydroxyl groups on the polymer. (Melamine resins will, of course, react with carboxylic acid groups but again, this is a slower reaction and requires a higher temperature). An hydroxyl value of about 50 mg KOH/g is normally adequate to provide a reasonable cure schedule, although higher values will, of course, help to speed up the reaction. Too high an hydroxyl value will, in fact, affect the deposition by reducing the film resistance, so there is a practical upper limit depending on the deposition characteristics required.

23 июля, 2015

23 июля, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике