Monomer and any reaction modifiers are premixed and fed at a predetermined rate into the reaction vessel containing solvent maintained at reaction temperature. Initiation is fed to the reaction vessel at a rate contiguous with the premixed monomer addition.

|

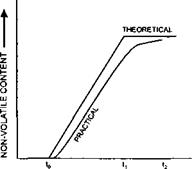

TIME ———— ► Figure 1 -67 |

Reaction conditions in commercial polymerisations are selected to favour rapid controllable conversion of the monomer and this, together with a timed, uniform feed rate, restricts the build-up of unreacted monomer.

7 июля, 2015

7 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике