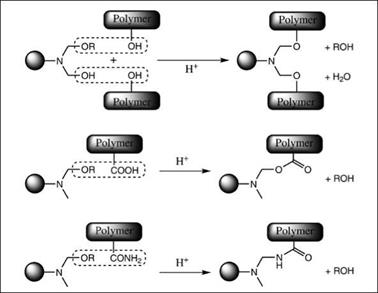

Amino resins, being thermosetting materials, can self-polymerize, but this results in a transparent but very hard and brittle polymer network that is not useful for coatings. Therefore, since their introduction, aminoplasts have been used as cross-linking agents for primary film forming resins such as polyesters, alkyds, epoxies, epoxy esters and acrylics. Aminoplasts are predominantly used with polymers having hydroxyl functionality (-OH), though other functionalities such as carboxylic acid (-COOH) and amide (-CONH2) are also used. See Figure 2.26 for the possible reactive sites. The crosslinking reactions need different types of catalysis and curing temperatures. For example, for cross-linking various functional groups in acrylic resin with hexamethoxymethyl melamine at 150 °C, the general order of reactivity of functional groups in co-resins is — OH > — CONH2 > — COOH in the presence of a strong acid catalyst, while in the absence of catalyst, it is -COOH >> — CONH2 > — OH.

During the cross-linking process, the film forming reactions involved are mainly of two types: polymer-aminoplast cross-linking and aminoplast-aminoplast cross-linking. The reactions involved between aminoplast and polymer are represented schematically in

|

|

Figure 2.27. The competitive self-condensation reaction will also occur between aminoplast molecules; however, the extent of such reactions will significantly depend on degree of alkylation of the aminoplasts, among other factors.

Urea resins are more economical and faster curing than other aminoplasts, but the final cured films have poor water resistance. They find main applications in wood finishes and in paper coatings due to their faster curing and lower curing temperatures. Ambient cured systems are also designed by using UFs and an alkyd or polyester with higher levels of very strong acid catalysts. These types of systems are supplied in two packages, with a solution of catalyst in alcohol supplied separately, that need to be mixed just prior to the application. Due to their low cost, they are also used in general — purpose low-bake industrial finishes.

MFs are the most widely used amino cross-linkers in the coating industry due to good mechanical properties, good chemical resi-

|

|

stance, excellent durability and good gloss of their cured coatings. A higher cross-link density compared with the UFs can be obtained with MFs because of the use of hexa-functional melamine. Most of the classical MFs used are partially butylated or isobutylated polymeric products that undergo self-cross-linking in addition to crosslinking with co-resins. Depending on their composition, these types of cross-linkers may have very high viscosity and hence a higher solvent content. Therefore, with development of high-solid and waterborne polymeric systems, use of highly methylated MF crosslinkers has gained considerable attention. Though they require very strong acid catalysts and higher curing temperatures, their lower tendency for self-cross-linking make them suitable for designing coatings with very good flexibility and toughness. These crosslinkers have low viscosity and they are compatible with highly polar as well as waterbased resins, making them excellent candidates for high-solid and waterborne coating systems. Among the most commonly used such products are hexamethoxymethyl melamine resins, which have secured a special place in the coating industry. Partially methylated MFs have also been developed to improve the cure response, but they have a tendency for self-cross-linking. Highly alkylated mixed ether MFs are used to achieve a performance that is a compromise between the highly methylated and butylated products. Popular applications of MFs include automotive coatings, coil coatings, wood coatings and industrial finishes.

BF cross-linkers are used where a combination of film flexibility and hardness is required along with good resistance to corrosion, humidity and chemicals. Due to their high cost and poor exterior durability, their use is limited to specific applications where the above merits are of prime importance and exterior durability is not a concern, such as internal can linings, coil coatings (primers only) and electro-deposition primers.

Demand for high performance amino cross-linkers with low formaldehyde release and high solid content led to development of GF cross-linkers. Highly alkylated GFs are cross-linkers with good storage stability, excellent adhesion to metallic substrates, and anticorrosive properties coupled with a low formaldehyde release during curing. Important applications of GFs include high-solid,

high performance coatings, automotive primers, coil coatings and coatings for appliances.

It should be noted that despite their widespread acceptance in the coating industry as a cross-linker of choice for many high performance coatings, aminoplast cross-linkers face many challenges. In the most developed countries, the trend is away from formaldehyde — based polymers due to the highly toxic nature of formaldehyde.

22 сентября, 2015

22 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике