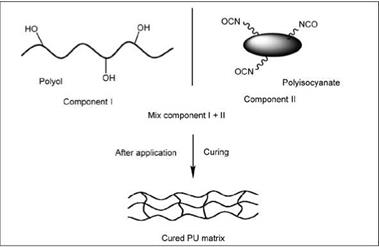

Two-component (also called by such terms as 2K, plural component, two-can, and two-part) polyurethane coatings are among the most popular types, and such coatings are offered in two separate cans that are required to be mixed in specified proportion just prior to their use (Figure 2.63). Since polyols and isocyanates are reactive at ambient temperature, these two components are packed (in precisely calculated stoichiometric amounts) in two separate cans. Due to the

|

Figure 2.63: Schematic representation of two-component polyurethane resin system |

high reactivity of isocyanate components and hence possible stability problems, all other coating components, such as pigments, solvents, additives and catalyst, are generally added to the polyol component.

Once the two components are mixed, the viscosity of the system will gradually increase due to an increase in MW and cross-linking as a result of formation of polyurethane. After reaching its pot life, the product can no longer be applied due to excessively high viscosity and/or cross-linking. Therefore, such products have to be formulated to a specified pot life. After application of the coating, the polyurethane formation reaction continues and results in a dry coating within a few hours. Properties of coatings such as hardness, flexibility, chemical resistance, pot life and cure time can be balanced by using the appropriate types of isocyanate and polyol components, solvents, additives, pigments and catalyst. Two-component-polyurethane coatings still have limited shelf-life due to the presence of the very reactive free isocyanate in one of the cans.

19 октября, 2015

19 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике