This is an interesting class of pigments that are capable of producing special color or visual effects when used in coatings. Special effect pigments are of two types: pearl luster and interference pigments. They are based on natural or synthetic materials that exhibit outstanding qualities of luster, brilliance, and iridescent color effects. Interference and pearlescent pigments cause color shifts that depend on the angle of view. The effect mimics pearls or fish scales, which consist of alternating transparent optically thin layers of CaCO3 and protein that have different refractive indices. These natural pearlescent pigments have been used for centuries in the form of natural pearl essence, which is isolated as a silky lustrous suspension from fish scales. They are very expensive because of the extensive extraction process and very low yield. They are generally used exclusively for expensive cosmetic applications.

Synthetic special effect pigments are either single-crystal platelets (substrate-free pigments) with high refractive index or platelets of low refractive index coated with an optically thin layer of material with a high refractive index (called coated substrate pigments). The optical effect produced by these pigments is attributed to their platelet shape as well as the reflection and refraction of light at the pigment-binder interface and, in the case of the latter type, at the phase boundaries within the particle itself.

Substrate-free effect pigments include basic lead carbonate (Pb(OH)2-2PbCO3), bismuth oxychloride (BiOCl), micaceous iron oxide (a-Fe2O3) and titanium dioxide flakes (TiO2). All of them have a settling tendency due to their high density. Basic lead carbonate flakes are not used these days due to their low chemical stability and toxicity. Bismuth oxichoride has limited light stability that can be improved by cerium doping. Its dull, dark brown color is the limitation for micaceous iron oxide, but the color can be shifted to a more attractive reddish-brown by incorporating certain dopants. Titanium oxide flakes are very brittle and therefore not suitable for applications where high mechanical stresses are exerted.

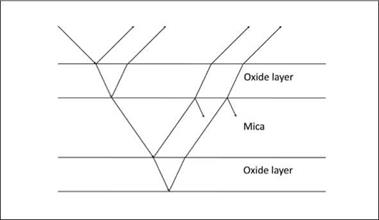

Coated substrate pigments are the dominant class of special-effect pigments in recent commercial applications. Based on the type of substrate being coated, this class of special-effect pigments can be categorized into three groups — mica-based pigments, silica flake pigments and alumina flake pigments. A schematic representation of the interference effect of such pigments is illustrated in Figure 3.8.

|

Figure 3.8: Schematic presentation of interference by pearlescent pigments |

Among these groups, mica-based effect pigments are the largest. Mica acts as a support for deposition of optically thin layers of coatings with a high refractive index, such as titanium dioxide, iron oxide or multiple layers of these. Thus, the pigment particle behaves like two titanium dioxide platelets held together by mica. The interference color produced depends on the thickness of the oxide layer on the substrate. Also, when mica is coated with colored oxides such as Fe2O3, more intensely colored pigments are obtained.

Mica, being a natural product, does not have absolutely uniform surfaces on its platelets, which limits the amount of luster produced by these pigments. In order to produce stronger interference, silica flake pigments have been developed. The main advantages offered by synthetic silica flakes over the use of natural mica include uniform controlled thickness, no impurities and lower refractive index (1.46) than mica (1.58). High quality, thin hexagonal monocrystalline Al2O3 flakes are also used as a substrate for interference pigments.

In contrast to normal pigments, where colors are subtractive, interference pigments lead to additive color mixing. Also, particle size plays a vital role in the effect produced — smaller particles give a satin effect, while coarser ones produce a sparkle effect. In actual

coating formulations, transparent pigments are used with interference pigments, which produces a variety of two-color effects.

The latest category of special-effect pigments is diffractive pigments, in which interference is produced by diffraction technology. These pigments are produced by vacuum deposition on specially patterned surfaces.

24 ноября, 2015

24 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике