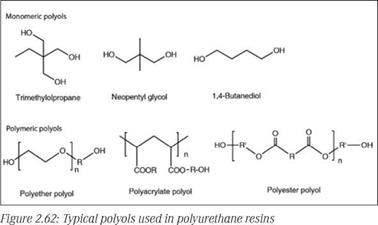

Polyols are materials with hydroxyl (-OH) groups. Polyols are very important components of polyurethane resins and control many mechanical, thermal and physical properties of their coatings, besides the overall cost. Like isocyanates, polyols for polyurethane resins include monomeric polyols and polymeric polyols (Figure 2.62).

|

|

Polyols with primary — OH groups are more reactive with isocyanates compared to those with secondary — OH groups. Tertiary alcohols have extremely low reactivity and they practically do not react with isocyanates. Monomeric polyols, due to their low equivalent weights, produce more rigid urethane linkages per unit weight and thus tend to produce harder segments in the polyurethane chains. Therefore, such polyols are also known as hard polyols. Polymeric polyols, on the other hand, have — OH groups spaced farther apart, and hence will produce fewer urethane linkages producing softer segments, and hence are known as soft polyols. Polyurethane coatings with varying hardness, flexibility and degree of elongation can be formulated using a proper balance of soft and hard polyols.

19 октября, 2015

19 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике