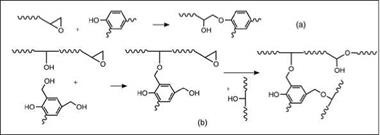

Both resole and novolac type phenolic resins are used to cure high MW epoxy resins to give a hard and tough film with very good chemical and corrosion resistance. Such systems are generally cured at high temperatures of about 150 to 200 °C. The phenolic hydroxyl groups in both resoles and novolacs can react with the glycidyl groups of epoxy resins; in the case of resoles, methylol groups contribute to cross-linking via self-condensation as well as by reaction with hydroxyl groups of epoxy resins (Figure 2.55). Such systems are very popular in coatings for food and beverage cans.

|

Figure 2.55: Curing of epoxy with (a) phenolic hydroxyl and (b) methylol groups of phenolic resins |

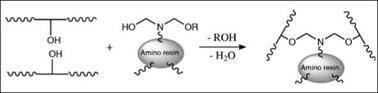

In an analogous thermally cured system, high MW epoxy resins are cured by reaction of their hydroxyl groups with methylol or alkylated methylol groups of amino resins (Figure 2.56). Melamine formaldehyde and urea formaldehyde systems are most common. While chemical resistance of these systems is lower than those of phenolic cured systems, their lower curing temperature and better color compared to phenolic systems is taken advantage of when faster cure speed is important.

|

Figure 2.56: Schematic representation of curing of an epoxy with an amino resin |

12 октября, 2015

12 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике