Epoxy resins prepared from the reaction between bisphenol A (BPA) and epichlorohydrin are commercially the most important ones, covering around 80 to 85 % of the volume of epoxy resins used in the industry. Various BPA epoxy resins available on the market primarily differ in their MW, and can be categorized as:

• Low MW: mainly used in adhesives, composites and some high — solid or solvent-free coatings

• Medium MW: most commonly used in conventional two-component epoxy coatings

• High MW: predominantly used for epoxy esters, powder coatings, can coatings and electrophoretic coatings

• Very high MW (also known as phenoxy resins): commonly used for thermoplastic epoxy lacquers.

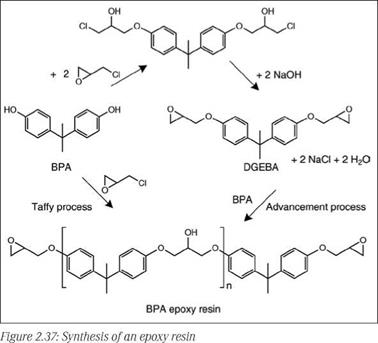

A reaction scheme for synthesis of the diglycidylether of bisphenol A (DGEBA) and higher MW epoxy resins is shown in Figure 2.37.

Epoxy resins with varying MW can be prepared by varying the molar ratio of epichlorohydrin to BPA. DGEBA is the lowest MW epoxy resin and is produced in high volumes. Pure DGEBA (average number of repeat units n = 0) tends to crystalize at room temperature (melting point 45 °C), and therefore, commercially important liquid epoxy resins are supplied with n « 0.1, which inhibits crystallization. The higher MW epoxy resins are more commonly prepared

|

|

by reacting DGEBA with additional BPA by what is known as the advancement process (Figure 2.37).

Epoxy resins have two sets of functional groups — two terminal epoxy groups and hydroxyl groups on the polymeric backbone. These reactive functional groups are utilized in modification or cross-linking reactions of epoxy resins. The aromatic structure in the backbone contributes to rigidity and hardness along with very good chemical, thermal and electrical resistance. The aliphatic sequence with an ether linkage imparts flexibility and toughness. While the generic structure shown is linear, the actual resin may have some degree of branching arising from side reactions of epoxy and secondary hydroxyls, particularly in the higher MW grades. As the n value increases, the MW, epoxy equivalent weight, hydroxyl content and melting point of the resin increases. The typical commercial grades of BPA epoxy resins are shown in Table 2.7.

30 сентября, 2015

30 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике