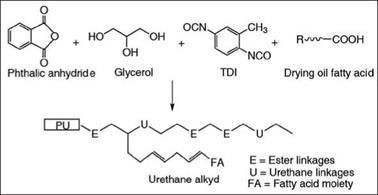

These resins are generally polyurethanes modified by drying-oil fatty acids. These types of resins are essentially urethane modified alkyd resins, and hence are also called urethane alkyds or uralkyds. Like alkyds, urethane alkyds dry by auto-oxidative polymerization, and their drying rate can be improved by use of conventional driers used for alkyds. A reaction scheme for preparation of a urethane alkyd is shown in Figure 2.66. Inclusion of urethane linkages in the alkyd resin structure brings about a number of beneficial properties in uralkyds. In general, uralkyds are faster drying and produce films with improved gloss and hardness. Thus, urethane alkyds are not true urethane resins but upgraded alkyds with remarkable performance benefits. However, due to the use of

|

Figure 2.66: A simplified reaction scheme for synthesis of urethane alkyds |

aromatic isocyanates, uralkyd based coatings have a tendency to discolor upon exposure. Uralkyds find applications as low-cost, fastdrying enamels, primers, wood coatings and many similar types of coatings.

21 октября, 2015

21 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике