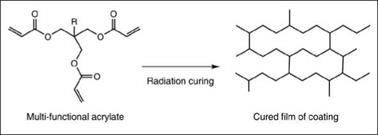

Radiation curable coatings are special types of systems that are cured by exposure of their wet films to high energy radiation such as UV light or an electron beam. The markets for such coatings, because of their rapid curing at ambient temperature, low energy requirement, and solvent-less composition, have been steadily growing and expanding in many new areas. The binder systems used for such coatings are currently dominated by those containing acrylate functional groups. Unlike the acrylic resins described above, the resins for radiation curable systems contain free acrylate groups with the unsaturated double bonds of acrylates still present. During the radiation curing process, cross-linking reactions occur through these free acrylate groups by radical polymerization, resulting in formation of a cross-linked network, as depicted in Figure 2.34.

|

Figure 2.34: Typical structure of an acrylate functional system for radiation curable coatings |

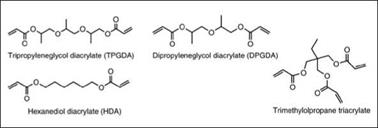

A typical resin for a radiation curable coating contains two or multifunctional acrylate oligomer(s) with MWs ranging from a few hundred to a few thousand grams per mole. These oligomers have a high viscosity depending upon their chemical makeup and MW. Low MW multifunctional acrylate compounds with very low viscosity are invariably added to the oligomers to reduce the viscosity of their formulations. A photoinitiator is also used in the formulation and produces free radicals upon exposure to radiation, which initiates the curing reaction. These low MW acrylates are reactive diluents (Figure 2.35), which both serve as solvents in reducing viscosity and become part of the cured film network by virtue of their reactive

|

Figure 2.35: Some commonly used monomeric acrylates (reactive diluents) |

acrylate functionality. Such systems thus do not require addition of solvents and hence can be supplied as 100 % solid systems.

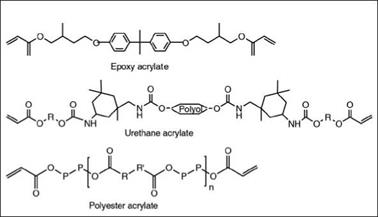

Commercial acrylate oligomers are available that have a wide range of chemistries, functional group (acrylate) content, and viscosity. Among the most commonly used oligomers are difunctional polyester acrylates, epoxy acrylates, polyurethane acrylate and polyether acrylates. The chemical structures of oligomers control such properties as viscosity, reactivity, and thermo-mechanical properties of cured films. For example, epoxy esters produce much harder films compared to polyether acrylate of comparable

|

Figure 2.36: Some examples of acrylate oligomers used in radiation curable coatings |

MW and acrylate content. Reactive diluents also play an important role in controlling viscosity of compositions, cure speed, and thermo-mechanical properties. Formulators of radiation curable coatings must select suitable combination of oligomers (Figure 2.36) and reactive diluents so as to attain desirable film properties for any given application.

27 сентября, 2015

27 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике