Acrylic resins, also known as acrylates or polyacrylates, are an important class of versatile resins used in a wide variety of architectural, industrial and specialty paints and coatings, sealants, adhesives, and elastomers. In general, their excellent resistance to sunlight exposure and water make them especially suitable for a number of end-use applications. Acrylic resins are commercially offered as solid powders or pellets, waterbased dispersions, and as solutions in organic solvents, including high-solid grades and photo-curable grades, and thus cater to a broad range of product technologies.

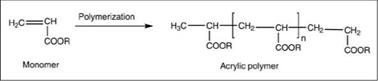

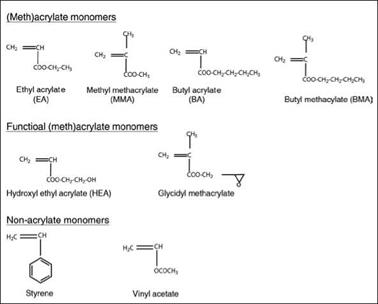

Typical acrylic resins are high MW polymers or copolymers of acrylate and/or methacrylate monomers prepared by radical-initiated chain — growth polymerization (see Figure 2.28). In addition to the (meth) acrylate monomers, other functional (meth)acrylate monomers as well as non-acrylate monomers (typically vinyl monomers) are frequently used in preparation of commercial acrylic copolymer resins to impart reactive functionality or special properties or for lower cost. Some examples of these monomers are shown in Figure 2.29.

The terms pure acrylics or 100 % acrylic resin is frequently used to differentiate acrylic resins derived strictly from (meth)acrylate

|

|

monomers from those derived from non-acrylate monomers in addition to (meth)acrylate monomers. The commercial availability of a large number of monomers makes it possible to prepare acrylic resins and copolymers with virtually unlimited possibilities. This allows manufacturers to customize these resins precisely to the requirements of the final product. For instance, using different combinations of monomers and processing conditions, acrylic resins with such a wide range of properties as fibers, plastics, coatings and elastomers can be prepared.

|

Figure 2.29: A few examples of monomers used in acrylic resins |

22 сентября, 2015

22 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике