The high prices that essential oils command lead, inevitably, to the temptation for less scrupulous producers and dealers to adulterate the product. Adulteration is sometimes referred to, euphemistically, as sophistication. By adding lower cost materials, but still asking the same high price for the mixture, the person perpetrating the fraud can stand to make considerable sums of money from an unsuspecting buyer. However, the major fragrance companies are sufficiently astute and technically competent to uncover almost all attempts at such fraud. The techniques used in adulteration vary from the crude to the very sophisticated, as evidenced by the following examples. The examples also illustrate some of the quality control (QC) techniques used routinely by the industry.

A supplier of ylang-ylang oil once tried to sell drums that contained only a small amount of the oil, the remainder of the drum contents being river water. This attempt at deceit was easily discovered, since QC samples are normally drawn from top, middle and bottom of drums, so one sample would be oil and the other two water.

Lavender oils are relatively inexpensive essential oils, but their major components are available as even cheaper chemicals and so the possibility to cheat does exist. Like all natural products, the composition

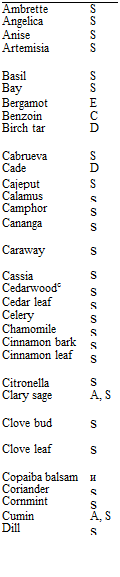

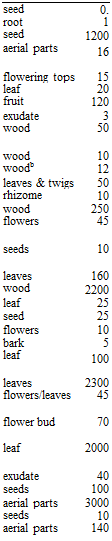

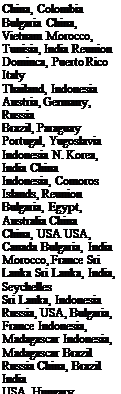

Table 3.2 Some of the more important natural fragrance materials

Approximate

Types of annual

process Plant part production Typical country

|

|

|

Oil useda extracted (tonnes) of origin

|

Table 3.2 Continued

|

|

Table 3.2 Continued

|

a A = absolutes; C = concretes and resinoids; D = dry distilled oil; E = expressed oil;

S = steam-distilled oil; T = tincture; U = untreated (however, these products are often boiled to free them from plant material). b The wood is juniper. c There are two main types of cedarwood sources for perfumery. One comprises plants of the Juniperus family and the other of the Cedrus family. The former are known as English, Texan or Chinese cedarwood and are produced principally in China and the USA. The leaf oils are extracted from this family. Chemically, the major components of these oils are based on the cedrane skeleton. The products obtained from members of the Cedrus family are known as Atlas or Himalayan cedarwoods. They are produced in North Africa and the Himalayas and the chemical structures of their major components are based on the bisabolane skeleton. d The different Eucalyptus species of importance to the perfumery industry contain different terpenes as their major components. The terpenes of each are related to the following major components: E. citriodora, citronellal; E. dives, piperitone, E. globulus, cineole; E. staigeriana, citral. e The oil and absolute are known as cistus. f There are three species of lavender which give oils of differing quality. They are known as lavender, lavandin and spike. g It is interesting to note that, in the case of orange, three different oils are produced from the same species.

varies. The percentage of the individual components present in the lavender oils depends on, for example, the area where the plant was grown, the rainfall that season, the harvesting method and so on. The analytical chemist responsible for QC of lavender oil therefore does not expect to see major components present at fixed levels, but rather within an acceptable range. Linalyl acetate, for example, is normally present in lavender oil at between 30 and 60%. Synthetic linalyl acetate is available for a fraction of the price of lavender oil, and so a supplier might be tempted to add some synthetic material to the oil and charge the full price for the mixture. This fraud is also relatively easily detected. Synthetic linalyl acetate is made, as is discussed later, from dehydrolinalool. The dehydrolinalool is hydrogenated over a Lindlar catalyst to give linalool. This hydrogenation, in theory, stops at linalool. However, a small amount of the substrate is fully saturated to dihydrolinalool, which does not occur in nature. Thus, the analyst examines the gas chromotography (GC) trace of lavender oil for dihydrolinalyl acetate. If it is present, then adulteration is suspected. The tell-tale component can be detected at extremely low concentrations, using GC-mass spectrometry (GC-MS) if necessary, since that technique is even more sensitive than GC alone.

Vanilla is a very expensive natural product, costing £5000 or more per kilogramme. The most important components of the vanilla bean, as far as flavour is concerned, is vanillin. Synthetic vanillin costs only a few pounds per kilogramme. Food labelling laws are very strict and the penalties for declaring a flavour to be natural when it is not, are very high. Not only can companies be fined for false declaration but also their directors are liable to imprisonment in certain countries, in particular in the USA. It is therefore very important that a company buying vanilla is able to verify for itself that the goods for sale are of natural origin.

One simple test is to measure the level of radioactivity from the sample. Synthetic vanillin is not radioactive. However, natural vanilla, like all natural products, is. This is, of course, because atmospheric carbon dioxide contains some radioactive 14C formed by exposure to cosmic radiation in the upper atmosphere. Plants then incorporate this into their photosynthetic pathway and produce metabolites which exhibit a low level of radioactivity. Synthetic vanillin is prepared from coal tar, which is not radioactive since the 14C has long-since decayed. However, unscrupulous dealers know this and can synthesize radiolabelled or ‘hot’ vanillin and dose it into synthetic material so that the level of radioactivity matches that of a natural sample. Another method of checking for naturalness must, therefore, be found. When plant enzymes synthesize molecules, they, like all catalysts, are susceptible to isotope effects. The vanilla plant is no exception and examination of the distribution of hydrogen and carbon isotopes in the vanillin molecule reveals that the heavier deuterium and 13C isotopes accumulate at certain specific sites. A suitable nuclear magnetic resonance (NMR) spectrometer can determine the isotopic distribution in a sample and the cost of using 2H, 13C and 14C-labelled synthetic materials to replicate the NMR spectra and radioactivity of natural vanillin in a synthetic sample are not financially attractive. Furthermore, the 2H and 13C labelling patterns in the vanilla bean are different from those of other natural shikimate sources and so the NMR technique can also distinguish between vanillin from vanilla and vanillin produced by degradation of lignin. (Lignin is the structural component of wood and is therefore very inexpensive.)

As each opportunity for adulteration is blocked by analysts, the crooks seek new methods and so the QC analyst must think proactively to keep ahead.

28 июня, 2015

28 июня, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике