Light energy is defined by its wavelength and intensity. The wavelength is measured in nanometres (10-9 metres) and the intensity is measured in milliwatts/cm2 (mW/cm2). In order to cure a UV adhesive it is important to give the adhesive the correct wavelength (to match the photoinitiator) and the correct dosage of UV light. The total exposure (dosage) is measured in millijoules/cm2 (mJ/cm2) [watts x seconds = joules].

UV light is part of the electromagnetic spectrum and the wavelength is between 100 nm (nanometres) and 700 nm (Figure 1.9). Traditionally UV light is split into three categories:

• UVA (320-390 nm)

UVA is part of natural sunlight and most ordinary light bulbs will produce a small amount of UVA. Human skin will tan under UVA but at low intensities UVA is not harmful.

• UVB (280-320 nm)

UVB is also found in sunlight and this has a shorter wavelength and a higher energy and thus is more aggressive than UVA. Many suntan lotions will filter out UVB.

• UVC (200-280 nm)

UVC has the highest energy and is therefore the most harmful of the UV wavelengths and can produce skin cancer. Lamps producing this wavelength should be properly shielded to protect operators.

The Electromagnetic Spectrum

![]()

![]()

1 1/100 10-5 eV

1 1/100 10-5 eV

; -*——— Radiation

I Visible Energy

!Light Infra-Red Microwaves Radiowaves

I—- 1————- 1———— 1————

103 104 105nm

; Wavelength———- ►-

Figure 1.9 The electromagnetic spectrum

In addition to the three traditional UV categories, there are two further categories within the electromagnetic spectrum:

• Vacuum UV, which exists only in a vacuum between 100 and 200 nm.

• UVV (UV Visible) (390-470 nm)

This is at the visible end of the UV spectrum (the human eye can see light in the range 400-700 nm) and is not as harmful as UVA except at high intensities.

|

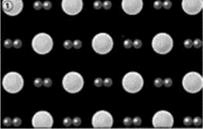

A UV adhesive contains photoinitiators and it is important that the adhesive is provided with sufficient UV energy to split the photoinitiator, thus creating a free radical which initiates the polymerisation of the adhesive. Figures 1.10-1.12 give a diagrammatic representation of the cure process.

|

|

|

Note that it is important to measure the UV intensity at the bond line and not at the UV source as the intensity can be significantly reduced away from the light source and especially as it passes through the substrate (Figure 1.13).

Most UV adhesives require a minimum intensity at the bond line of 5 mW/cm2 but for most production applications the recommended intensity should not be less than 50 mW/cm2. Some light guide units will produce even higher intensities (>5000 mW/cm2) and, in general, the higher the intensity, the faster the cure.

As a general rule, the amount of energy required to cure a UV acrylic adhesive is 1500 mJ/cm2. So if the intensity of the UV light (at the bond line) is 100 mW/cm2 then the cure time should be 15 seconds.

Many of the original UV products (developed for glass bonding) cured at a wavelength of 365 nm (UVA) and this was ideal for glass bonding as the UVA wavelength is transmitted by most grades of glass. Many plastics, however (e. g., polycarbonate), can act as a UV filter (especially to UVA and to shorter wavelengths) and thus the UV adhesives with UVA photoinitiators would not cure under polycarbonate (see Figure 1.14).

The wide use of polycarbonate and flexible PVC in the medical industry resulted in the development of a range of adhesives which were not only considerably more flexible but also cured at the visible end of the UV spectrum (UVV) 390 — 470 nm, thus overcoming the problem of absorbance at shorter wavelengths. Whilst these products are described as ‘visible light curing’ adhesives, it should be noted that an investment in UV equipment is still required for rapid curing.

Figure 1.14 Glass will filter out all wavelengths <300 nm

and many plastics will filter out <400 nm

5 сентября, 2015

5 сентября, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике