In most situations, if ‘substrate failure’ is achieved (Figure 10.9) then no more could be asked of the adhesive as the adhesive bond is stronger than the plastic or elastomer bonded.

Sometimes, however, the adhesive will change the mechanical properties of the complete assembly, especially if the adhesive creates highly stressed regions at the periphery of the bonded joint.

With an elastic modulus of 1-2 GPa, a typical plastic (e. g., polycarbonate) is over 100 times more flexible than steel for identical shaped components. In a lap shear joint (Figure 10.10), this flexibility means that more bending and differential shearing (compared to steel) will occur in the bonded joint as the assembly is placed under load.

|

Figure 10.9 Substrate failure |

|

Figure 10.10 Bonded lap shear joint |

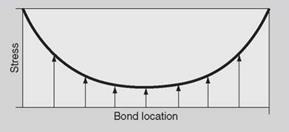

This flexibility leads to increased stress concentrations near the ends of the overlap (Figure 10.11) and these can sometimes lead to substrate failure at relatively low loads. These high-stress concentrations can be reduced in many cases effectively by careful selection of joint design parameters. Most important among these are the elastic modulus of the adhesive, length of the overlap and thickness of the bond line between the two substrates. A lower modulus adhesive reduces the stress concentrations by accommodating the relative motion of the two substrates with greater shear compliance. The extreme case is when a rubbery adhesive is used. Such an adhesive is so rubbery that shear deformations can be accommodated without creating significant stress concentrations. But an adhesive this flexible may not be able to accommodate the structural loads on an actual assembly without excessive deformation.

|

Figure 10.11 Stress distribution across a lap shear joint |

Adhesives can also stress crack or ‘craze’ certain plastics and this can also induce premature failure of the substrate. This generally happens whilst the adhesive is uncured and the plastic part is pre-stressed due to abrupt changes of section. The liquid adhesive softens and weakens the plastic leading to the formation of cracks and the liquid adhesive then penetrates these cracks causing further damage. With fast-curing adhesives, this is less likely to occur as once the adhesive has cured it is essentially a thermoset plastic (or thermoplastic) itself and is therefore inert. Amorphous thermoplastics are more prone to stress cracking than others and so it is important therefore to ensure that the adhesive is compatible with the substrate.

20 января, 2016

20 января, 2016  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике