The durability of UV-curing acrylic adhesives will again depend very much on the substrates bonded, the joint design and the gap between the parts. Some UV adhesives with silane additives are specifically formulated for the bonding of glass, whereas other UV-curing adhesives are best suited for plastics. UV adhesives generally will show good adhesion and thus good durability on PVC, polycarbonate, ABS and polysulfone but are typically not the most appropriate adhesive for bonding to elastomers.

|

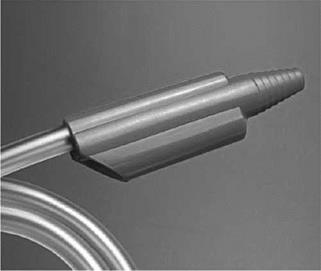

Figure 9.5 Bonding polyurethane tubing to poly(vinyl chloride) (PVC) connector (this part is gamma sterilised) |

UV adhesives are sometimes used for the bonding of ‘point of sale’ display stands as the UV adhesive can give strong, clear bonds with fast cure. UV adhesives have also been used for the bonding of automotive sub-components, especially lamp housings and for the potting/encapsulation of small electronic parts. High temperatures (>150 °C) may discolour UV acrylics and for these higher temperature applications a UV-curing silicone should be considered.

30 декабря, 2015

30 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике