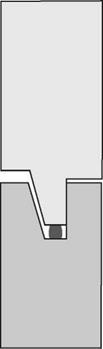

A tongue and groove (or double lap shear) joint (Figure 5.9) can be an ideal joint design for many applications, especially for bonding a lid onto a box. The adhesive can be dispensed into the groove, thus ensuring positive location of the liquid adhesive and when the joint is closed and the adhesive cured, the adhesive is essentially under shear loading and so will have high strengths. Note, however, even with this design which would appear to allow symmetrical loading, under high load the substrates may distort and thus subject the adhesive to a cleavage/peel load [2].

The wall thickness of the substrate will define whether there is sufficient width to include a double lap shear joint and if the thickness is less than 3 mm, it may well be difficult to achieve the tolerances required.

One of the issues that can occur with a tongue and groove joint is allowing for where the adhesive will flow to when the joint is closed. In Figure 5.9, when the joint is closed, excess adhesive has nowhere to flow to and may therefore spill out and impair the aesthetics of the assembly.

|

|

|

|

|

|

|

|

Figure 5.10 A modified tongue and an offset ensures the adhesive finds the easiest

path to the larger gap and thus minimises excess adhesive outside the joint

In Figure 5.10, the design has been modified slightly to allow for the adhesive to flow into a slightly larger gap, thus improving the aesthetics of the joint.

29 октября, 2015

29 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике