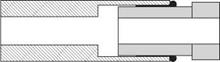

In many cylindrical bonding applications involving plastics, it is common practice to dispense the adhesive onto the inner (male) substrate and then close the joint with a rotating action. This in principle is fine but invariably excess adhesive is applied and the excess will be forced out of the joint as shown in Figure 5.13.

|

|

|

L

Figure 5.12 Tube bonding with long engagement lengths

|

|

|

|

|

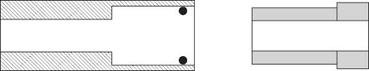

Figure 5.14 Applying adhesive to the female component |

Perhaps the easiest option is to control the dispensing carefully to minimise excess adhesive (see Section 8.1.5). However, one option to overcome excess adhesive being pushed outside the joint is to apply the adhesive to the inside of the female component (Figure 5.14).

In this case (Figure 5.14) the adhesive tends to get pushed along the component and will end up on the inside. This may in its turn cause issues with the possibility that the adhesive may block or interfere with other fluids passing through the connector.

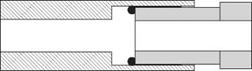

A third option for cylindrical component parts is to design in a small recess so that the adhesive has somewhere to escape to when the joint is closed (Figure 5.15).

30 октября, 2015

30 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике