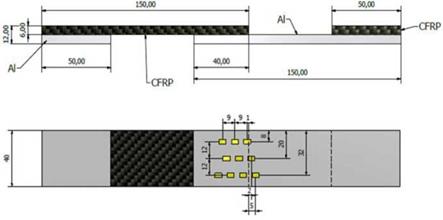

In this case, an aluminum-carbon fiber reinforced polymer (CFRP) adhesively bonded SLJ was investigated [46]. Woven CFRP adherent having 0° ply orientation was bonded with an aluminum adherend by epoxy structural adhesive DP 760.

The detailed shape and dimensions of the specimen are given in Figure 8. Four specimens were manufactured. Two specimens were without any artificial defect and each of the other two specimens had an artificial crack which was created in one side of the joint by inserting a Teflon tape into the adhesive.

|

Figure 8. Detailed dimensions (in mm) of the specimen. |

Application of an Array of Strain Sensors

In this case, two types of sensors were applied in order to reconstruct the strain distribution along the backface of aluminum substrate of the joint. Both electrical strain gauges (SG) and FBG sensors were used on different specimens. Strain gauge arrays were used for two specimens, one without any defect and another with an artificial of 5.7 mm. FBG arrays were used for other two specimens, one without any crack and the other with a pre-crack of 10 mm.

Due to dimensional restrictions and to leave space for wiring of strain gauges, 3 strain gauge arrays containing total 10 strain gauges were used in the bonded region as shown in Figure 8. In the case of FBGs, due to their multiplexing capability, an array of 10 FBG sensors inscribed along a single fiber was used. While installing the FBG array, the positional distance between the sensors was kept equal to that between the electric strain gauges.

28 декабря, 2015

28 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике