First of all, by looking at Figures 4-5, observing the curves for PFJs joints, it can be remarked that the peak of the release force is often lower than the coupling load maximum value. This result is consistent with previous

experimental outcomes [3] and can be explained, observing that the pin insertion implies chopping the roughness crests, with the consequence that the actual interference (Z) is reduced (as explained also in the Materials and Methods section). Therefore, in the release condition the pressure acting on the mating surfaces and the resulting friction forces are lowered. The determined values of pressure are comparable to reference values for steel to steel contact and so are the resulting values of /лА [3].

25 z

20

■o

u!

u!

15

О О

10

>

(Л

<u R

5

тз <

0

25 z

20

LL

15

О о

10

>

(Л

5

тз <

0

The subject of this paper consisted in the investigation of the influence of the ER on the adhesive performance. Thus, the main issue of discussion consists in the comparison between the determined values for the shear strengths zad and the K ratios. By looking at the histograms in Figures 3 and 6,

it can be observed that the values are very close to each other and that the intervals are often overlapped. These data distributions undoubtedly suggest that the ER has a poor impact on the variation of the mentioned parameters. Moreover, the data were processed by the statistical tools of Design of Experiment: in particular, the Analysis of Variance (ANOVA) and the Fisher test (F-Test). The combined use of these tools can be regarded as the most suitable approach to state if a factor has an impact (i. e., a significant effect) on one or more response variables. From the methodological point of view, full details are provided in the Appendix Section, in [22] and in [20, 23-27], where these tools were successfully applied to compare data populations. In the present study the ANOVA and the F-Test were applied to process the experimental data, in order to establish if the ER has an effect on the adhesive strength and on the Kj ratio. The results of the first and the second campaigns on HJs were taken into account, thus investigating the effect of ER at different interference levels. All the analyses confirmed that no significant differences can be observed (at the 5% significance level), i. e., the impact of ER is negligible. The response of ER being not significant is confirmed also by the linear relationship between the amount of force on the adhesive, Fad, and ER, considering the results of both experimental campaigns on HJs. The related trends are shown in Figure 8: it can be remarked that the linear correlation coefficient (R2) is almost 1 (indicating perfect linearity) in the second case.

This result can be explained by observing that, assuming rad as an invariant, Fad must be proportional to A. By considering Eq. (4), A is undoubtedly proportional to the coupling length LC, which is proportional to LCIDC, i. e., to the engagement ratio. The relationship is summarized in Eq. (12).

Fad X A X Lc X TC = ER (12)

DC

Since it was proved that the ER is ineffective, it seems to be correct to consider the averaged values (of rad and Kj) over the entire specimen populations, when comparing the adhesive response in the first and in the second experimental campaigns. It was pointed out that the shear strength is about 18MPa considering the first set of data and 26MPa, in the second case, with an increment of almost 50%. The retrieved values must be discussed in the light of the different interference levels: 18 qm in the first case and 5qm in the second one (considering the mean values of the theoretical interference U).

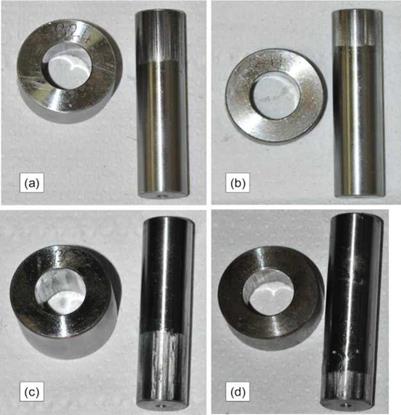

A possible reason for a worse performance when the interference level is higher is that during the press fit operation a certain amount of adhesive is stripped away from the mating surfaces, thus reducing the actual bonded area. This effect is clearly much more reduced when the interference level is low, or when the coupling procedure is conducted by different techniques, e. g., shrinkfitting [12]. This outcome is consistent with the results in [20], where it was pointed out that a high interference level, expensive for production, is usually not suitable to increase the joint resistance. Photos of a shaft and a hub (ER=1.7) after decoupling are shown in Figure 9 (a) with reference to the first campaign, and in Figure 9 (b) with reference to the second. It can be easily observed the adhesive polymerization is much better in the second case, thanks to the lower interference level.

|

Figure 9. Adhesive polymerization compared in specimens of different sizes with a higher (a, b) and a lower (c, d) interference. |

Finally, the ratio K is slightly increased (from 1.09 to 1.17), as the interference decreases, indicating a better adhesive response, however it does not encounter strong variations. The retrieved range for K is consistent with that in [14]. Therefore, Kj confirms to be a very useful parameter to predict the HJ static strength, once the maximum coupling load is known (measured by the load cell of the hydraulic press during the assembly phase). The results of this research confirm that this prediction is reliable, also when the ER has values far from 1.

The last remark regards the results of the third campaign, involving pin — collar specimens. No significant differences were also observed between the estimated shear strengths. Moreover, the determined values, around 24 MPa, are in agreement with the expected adhesive performance in pin-collar applications [16].

The subject of the present research was to investigate the effect of the ratio between the coupling length and the coupling diameter, namely the engagement ratio, on the response of a high strength single component anaerobic adhesive.

The issue was tackled by manufacturing and testing press-fitted and adhesively bonded joints, namely mixed joints (considering two levels of interference), and pin-collar samples.

The results were processed for the determination of two key design parameters: (i) the adhesive shear strength and (ii) the ratio between the release force and the coupling load. Statistical tests applied to the experimental results led to the conclusion that the engagement ratio has no effect on the joint strength, both with and without interference.

Considering the results of mixed joints, it was found out that the strength is increased from 18 to 26MPa (+50%), as the interference is decreased from 18 to 5 pm (considering the mean values of the theoretical interference U). This result is consistent with previous researches and may be explained with reference to the occurrence of the adhesive being partially stripped away during coupling.

Finally, the aforementioned load ratio also proved to be independent of the engagement ratio and to stand in the interval of about 1.1 to 1.2. From the point of view of joint design, this result makes it possible to reliably predict the decoupling force, based on the measured force upon coupling, even when the engagement ratio is far from 1.

6 ноября, 2015

6 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике