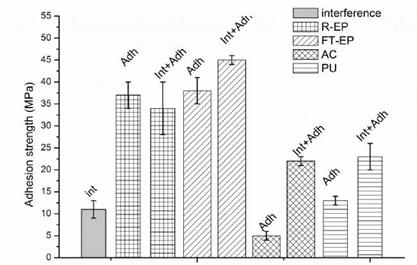

The importance of the adhesive contribution was more clear by the experimental investigation carried out on different adhesive systems. The mean adhesion strength values of the hybrid and clearance joints bonded with different adhesives were extrapolated and the related data are reported in figure 11 (Gallio et al., 2013).

From figure 11 it was possible to observe that the different adhesives presented a diverse behavior in the presence of the same interference level. Indeed, a similar interference contribution for every hybrid system could be assumed, taking into account a mean interference value of 17 ± 4 цт among the specimens. The resultant total strength of the hybrid joints changed on the basis of the adhesive type.

|

Figure 11. Comparison between the adhesion strength values of all the hybrid and clearance joints bonded with different adhesives. The interference contribution is labeled as “Int”, the bonded with clearance systems as “Adh”, the hybrid systems as “Int+Adh” (with permission of Gallio et al., 2013). |

The hybrid joints prepared with the FT-EP, AC and PU adhesives presented an increase in the adhesion strength with respect to the unbonded samples. The use of the FT-EP adhesive provided values of maximum decoupling load four times higher than those of the interference alone. In the case of the PU adhesive, the interference decoupling load was doubled in the hybrid joints. The AC adhesive presented the highest resistance improvement in the presence of the interference-fit compared to its performances in clearance condition because of its anaerobic curing mechanism (Gallio et al., 2013).

The R-EP was the only adhesive that seemed to be negatively affected by the interference. This result was surely affected by the high data dispersion obtained with the samples bonded with this adhesive. This recorded dispersion was probably due to the quantity of this adhesive able to remain inside the joint during the press-fit coupling. This hypothesis was confirmed by the analysis of the fracture surfaces of every hub and shaft after the decoupling. In the majority of cases, the shafts and the hubs presented some cured adhesive residues on the mating surfaces. In the case of FT-EP, AC and PU samples, the cured residues were present in a similar morphology on both the hubs and the shafts. On the contrary, different residue quantities of R-EP remained on the shafts of the various samples (Gallio et al., 2013).

The spreading of the adhesive in interference fit joints depends on the flow properties of the adhesive that are studied by rheology. For what concern the rheology of the adhesives tested in this work, the FT-EP, AC and PU were classified as thixotropic (3M Company, n. d.; Henkel Ag & Co. KGaA., 2011; Huntsman Corporation, 2013), whereas this characteristic was not declared from the supplier in the case of the R-EP adhesive (Henkel Ag & Co. KGaA., 2011). Thixotropic adhesives are capable of reversible solid-liquid transition: they are non-sag pastes that lower their viscosity when subjected to mechanical stresses (Petrie, 2007). In a rest condition and under low shear forces, their particles form a network structure that breaks down when a critical shear rate is reached (Fredrickson, 1964; Gupta, 2000). Generally a low viscosity is recommended in closer joints, while a high viscosity is preferable when a gap filling is required (Henkel Ag & Co. KGaA., 2011). During the press-fit coupling, considerable stresses were developed at the interface, therefore a thixotropic behavior could be advantageous. Probably the R-EP adhesive could be spewed away of the joint in a greater extent with respect to the other, thixotropic adhesives. Further studies have to be carried out to deeper analyze the relation between adhesive rheology and its residual quantity in the junction.

18 сентября, 2015

18 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике