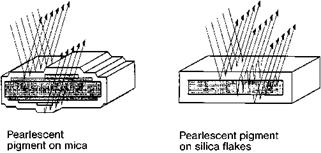

Instead of mica, SiO2 flakes can be used as a substrate for special effect pigments. The SiO2 flakes are produced by a web-coating process. Synthetic SiO2 flakes offer three advantages over the use of natural mica: 1. The thickness of the SiO2 substrate can be controlled in the preparation so that a pigment with a true optical three-layer system is obtained. The interference color of these systems is stronger than that with the conventional mica pigments for which the effect of the mica is “wiped out” by a broad thickness distribution. 2. As synthetic substrates they do not have the small iron impurities that cause the slightly yellow mass tone of natural mica. 3. SiO2 has a

|

Tab. 5.18: Functional metal-oxide pigments.

|

lower refractive index (1.46) than mica (about 1.58) and, therefore, leads to a stronger interference effect [5.150-5.152]. Figure 5.21 shows a cross-sectional diagram of metal oxide coated on mica and metal oxide deposited on silica flake pigments. The new properties available with silica flake pigments can be summarized as follows:

• Improved substrate characteristics

— Uniform and controllable substrate thickness

— Smooth and uniform substrate surface

— Transparent substrate with no mass tone color

• Improved reflection and refraction of light

• Improved chromatic strength and purity

• New color travel behavior

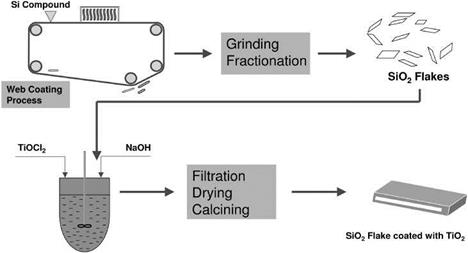

The silica flakes are manufactured by a web-coating process as shown in Figure 5.22. The web, moving at a controlled speed, is wet with an aqueous solution of a silica compound. The film on the web is dried to form a stable coating layer that can be selected to be between 50 nm and 1000 nm thick by adjustment of process parameters. The layer is then removed from the web and processed further to generate flakes that are fractioned and coated. The transparent flakes have a relatively low refractive index. However, they provide an excellent substrate for coating with the relatively high index metal oxides such as titanium dioxide and iron oxide. The metal oxides are applied in a standard precipitation-coating process producing high performance pearl luster pigments.

|

Fig. 5.21 Schematic cross-section of metal-oxide-coated pigments. |

|

Fig. 5.22 Process for manufacture of transparent silica flakes. |

Titania is deposited as hydrated titanium oxide on the surface of the SiO2 flakes. The thickness of the layer is monitored and precisely controlled. After drying and calcining, anatase is formed and a specific color is produced corresponding to the film thickness. The anatase modification is used in the cosmetic industry. In principle, the manufacturing process is similar to the “anatase” procedure. However, a thin intermediate SnO2 layer is applied to the surface of the SiO2 flakes before the TiO2 deposition. The SnO2 layer has a rutile structure which seeds epitaxy of the TiO2 rutile modification with its higher refractive index, brilliant color intensity and superior light stability. Consequently, the rutile pigments are preferred when these properties are advantageous.

SiO2 can be coated not only with TiO2 but also with other metal oxides that are deposited from hydrolysable salts. Iron(III) oxide is deposited as hydrated iron oxide on the transparent silica flakes. Subsequent drying and calcining produces a-Fe2O3

(hematite) layers on the flakes. The high refractive index of iron oxide generates strong interference effects and, in conjunction with the mass tone, brilliant red pigments.

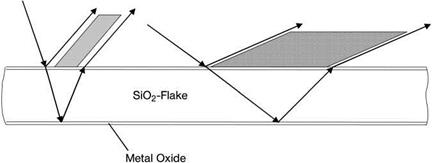

Two extraordinary optical effects are achieved by the combination of transparent silica flakes selected for precise uniform thickness and controlled depositions of metal oxide coating layers. The color of these pigments exhibits extreme angle dependence, and objects painted with them will change appearance with the direction of lighting and the location of the observer. Color changes from gold-silver to green, to green — blue, to dark blue are seen. The strong color travel is seen even under subdued lighting conditions. Figure 5.23 demonstrates how color travel is generated as a function of viewing angle with uniform silica substrates and metal oxide layer thickness. The angle-dependent color travel of three pigments through the “CIELAB” system is shown in Figure 5.24 for constant Fe2O3 deposition on SiO2 substrates of different thickness.

|

Fig. 5.23 Color variation vs. viewing angle of a SiO2 flake pigment with a very thin metal oxide layer. |

Improved color strength and very high luster are produced by the combination of precise thickness silica flake substrate materials, selected for their interference chro — maticity, and by deposition of titania or iron oxide coating layers of the precise thickness required to generate the same interference color. These pearl luster pigments show stronger chromaticity L*a*b*-values than can be produced with mica-based designs.

The SEM micrograph in Figure 5.25 shows a cross section through a TiO2 silica flake pigment. It shows clearly that both the SiO2 flake and the TiO2 layer thickness are precisely controlled.

6 января, 2016

6 января, 2016  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике