The iron oxide pigments described in Section 5.1.1 are either doped or coated with cobalt:

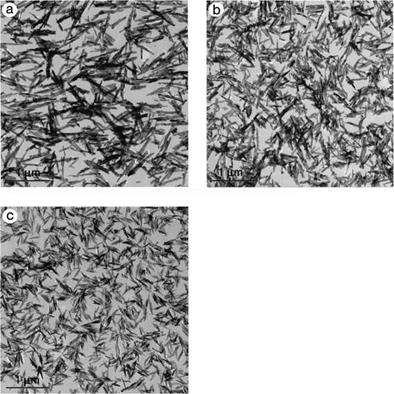

1. Body-doped pigments contain 2-5 wt.% cobalt that is uniformly distributed throughout the bulk of the pigment particles. It is either incorporated during production of the FeOOH precursor or precipitated as the hydroxide onto one of the intermediate products [5.13] using cobalt(II) salts as the cobalt source.

2. Cobalt-coated pigment particles (1.6-4 wt.% Co) consist of a core of y-Fe2O3 or non-stoichiometric iron oxide phase, and a 1-2 nm coating of cobalt ferrite with a

|

|

|

|

high coercivity [5.14]. The coating can be produced by adsorption of cobalt hydroxide, or epitaxial precipitation of cobalt ferrite in a strongly alkaline medium [5.15, 5.16]. Surface coated pigments show better magnetic stability than doped pigments.

5.1.2.2

15 декабря, 2015

15 декабря, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике