Barium ferrite is highly suitable for high-density digital recording, mainly because of its very small particle size and its very narrow switching field distribution. It also has a high anhysteretic susceptibility and is difficult to overwrite [5.38]. This is partly explained by positive interaction fields between particles in the coating layer [5.39].

The high anhysteretic susceptibility makes barium ferrite media particularly suitable for the anhysteretic (bias field) duplicating process [5.40].

Besides the thermal magnetic duplication process [5.41] used for CrO2 tapes, this is the second faster-than-real-time videotape duplicating process. The signal is transferred from the mirror master tape to the copy tape by applying a high-frequency bias field while the two tape coatings are in close contact with each other. The amplitude of the bias field is equal to the maximum coercivity of the copy tape. Under the influence of both the bias field and the field of the master tape, the magnetic particles in the copy tape are magnetized in exactly the opposite pattern to that ofthe mirror tape.

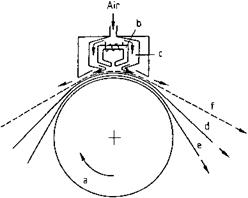

The current copy speed is ca. 100 times standard playing speed for VHS videotapes. Figure 5.4 shows the principle of the method [5.42].

Fig. 5.4 Anhysteretic duplication process [5.42]. a) Transfer drum; b) Transfer magnetic field head; c) Air chamber; d) Mirror master tape; e) Copy tape; f) Drive tape.

Fig. 5.4 Anhysteretic duplication process [5.42]. a) Transfer drum; b) Transfer magnetic field head; c) Air chamber; d) Mirror master tape; e) Copy tape; f) Drive tape.

Unlike many other magnetic materials used in high-density recording, barium ferrite, being an oxide, is not affected by corrosion [5.43]. Processing of the pigment can be problematic, e. g., applying orienting fields can easily lead to unwanted stacking of the particles, which has adverse effects on the noise level and the coercive field strength of the magnetic tape. A marked temperature dependence of the magnetic properties was a problem in the early days, but this can be overcome by appropriate doping [5.44].

5.1.6

21 декабря, 2015

21 декабря, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике