The channel black process, used in the United States since the late 19th century, is the oldest process for producing small-particle-size carbon blacks on an industrial scale. In 1961, the production of channel black was about 120,000 t. The last production plant in the United States was closed in 1976, due to low profitability and environmental difficulties. Natural gas was used as the feedstock. The carbon black yield was only 3-6%.

The gas black process was developed in the 1930s. It is similar to the channel black process, but uses coal tar oils instead of natural gas. Yields and production rates are much higher with oil-based feedstock. Degussa has used the gas black process on an industrial scale since 1935. Today, almost all grades are used as color blacks in printing inks, plastics, and coatings. High-quality oxidized gas blacks are of special interest, e. g., in deep black coatings.

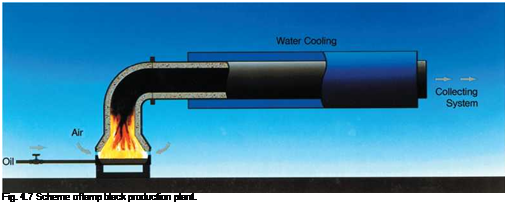

In the gas black process (Figure 4.6) the feedstock is partially vaporized. The residual oil is continuously withdrawn. The oil vapor is transported to the production apparatus by a combustible carrier gas (e. g. hydrogen, coke oven gas, or methane). Air may be added to the oil-gas mixture for the manufacture of very small particle size carbon black. Although this process is not as flexible as the furnace black process. Varying the relative amounts of carrier gas, oil, and air can lead to various types of gas black.

A gas black apparatus consists of a burner pipe approximately 5 m long, which carries 30-50 diffusion burners. The flames burn in contact with a water-cooled drum, where about half of the formed carbon black is deposited. This black is scraped off and transported by a screw to a pneumatic conveying system. A steel box, open at

|

|

the bottom, surrounds the gas black apparatus. At the top of it, fans suck the off-gas into filters, which collect the carbon black suspended in the gas.

The amount of air entering the apparatus can be regulated by valves in the exhaust pipes. Several gas-black apparatuses are combined to form one production unit. One oil vaporizer feeds the whole “group”. The production rate and the yield of an apparatus depend on the type of carbon black produced. For a typical RCC black, the production rate is 7-9 kg h-1 and the yield is 60%. The yield for high-quality color blacks is considerably lower (10-30%).

As a result of the contact with oxygen at high temperatures during production, acidic oxides are formed on the surface of the carbon black particles. In contrast to furnace blacks, gas blacks thus display an acidic reaction when suspended in water.

4.4.3

2 декабря, 2015

2 декабря, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике