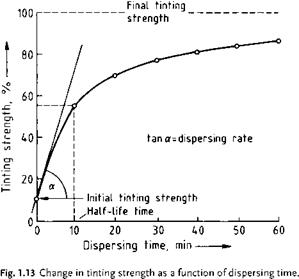

For standards see Table 1.1 (“Change in strength”). Dispersibilities of pigments may be compared by means of their dispersing resistance; dispersing equipment may be characterized by means of dispersing effects. Measurement can be based on the determination of half-life times in relation to the final tinting strength. The increase in strength, however, only gives the difference between the initial and final tinting strength [1.90]. Half-life times are functions of the dispersing rate. They are only valid for a given combination of dispersing equipment, dispersing process, and medium. Samples are taken from the millbase at specified stages in the dispersing process and mixed with a white paint based on the same binder material, or with a compatible white paste. The tinting strength is then determined (see Section 1.3.3) and a graph is drawn; development of tinting strength is plotted against the dispersion stages (Figure 1.13) [1.93].

Making use of equations used in the description of the kinetics of chemical reactions a quantitative description of the dispersion process can even be achieved [1.22] by defining three types of size reduction of large particles:

— against themselves (2nd order reaction)

— against the vessel walls and grinding bodies (1st order reaction)

— against the small particles already produced (interaction).

|

|

Pigment Volume Concentration (PVC) and Critical Pigment Volume Concentration (CPVC)

The pigment volume concentration (a) is the fractional volume of pigment in the total solids volume of the dry paint film:

Vp

Vp + Vb

where Vp is the pigment volume and Vb the binder volume. The PVC [1.94] is determined by separating the pigment fraction from a weighed paint sample by, for example, extracting the (liquid) binder with suitable organic solvents or solvent mixtures (sometimes using a centrifuge) or using combustion methods (sometimes including fuming with sulfuric acid) and analysis of the residue [1.95].

Under CPVC conditions, the pigment particles are at a maximum packing density, and the interstices are completely filled with binder. With smaller amounts of binder, the interstices are incompletely filled. The CPVC thus represents a pigment concentration boundary at which abrupt changes in the properties of the film occur.

The methods of determining the CPVC [1.96] are divided into two groups:

1. Methods based on the observation of a sudden change in properties in a series of PVCs (e. g., ion permeability, permeability to water vapor, color, gloss stability after coating with a silk-luster paint).

2. Methods based on the experimental production of the dense pigment packing typical of CPVC, e. g., by means of oil absorption, filtration, vacuum filtration, or by measuring the volume of the supercritical film.

12 сентября, 2015

12 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике