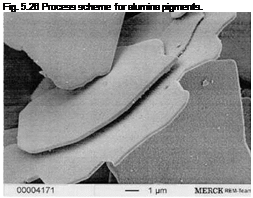

Thin hexagonal monocrystalline Al2O3 flakes can be produced by hydrothermal processes [5.150-5.152]. The thickness of the resulting flakes is not uniform. Therefore, the resulting coated pigments merely assume a dull pearlescence.

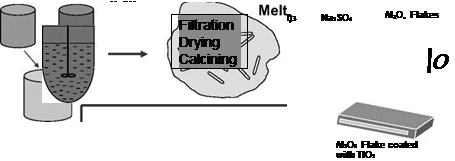

Al2O3 flakes of a higher quality are produced by the following steps (Figure 5.26). An aqueous solution of an aluminum salt is mixed with small quantities of a titanium salt and phosphate. After neutralization, a sol or suspension is obtained, which is

|

Fig. 5.25 Cross-section through a silica flake coated with TiO2.

then dried and heated to 900-1400 °C. After washing, very thin flakes are found which consist of corundum and show a high aspect ratio, a very narrow thickness distribution, and very smooth surfaces (Figure 5.27). The thickness can be controlled by the doping and reaction conditions. The resulting flakes are used as substrates in the aqueous-phase processes described above to prepare pearl luster pigments of very high luster. The advantage over a mica substrate lies mainly in the fact that all Al2O3 flakes have about the same thickness, which leads to true optical three-layer systems as for the SiO2 flakes. A very interesting crystal-like effect can be achieved by using alumina flake pigments in applications such as car paints.

|

|

Fig. 5.27 Electron micrograph ofA^Oj flakes.

7 января, 2016

7 января, 2016  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике