In the early 1900s, about 85 % of world dye requirements were manufactured in Germany, with other European countries (Switzerland, UK, and France) accounting for a further 10%. Eighty years and two world wars have seen dramatic changes in this pattern. Table 1.2 shows that, in weight terms, the Western European share of world production had dropped to 50% by 1938 and to 40% by 1974. It has declined even further with considerable production of commodity colorants moving to lower cost countries such as India, Taiwan, and China. However, since a large part of U. S. manufacture and some of others countries is based on Western European subsidiaries, their overall share remains at ca. 50%. Since 1974 many of the national figures have not been published, but those that are available indicate that 1974 was the peak production year of the 1970s, with 1975 being the nadir. World recession caused a 20% slump in production which has now been more than recovered.

Consequently, the figures of Table 1.2 are still applicable to the present day and show a decrease in Western European production and an increase in Eurasian production. More recent independent reviews [11,12] indicate a slightly lower world output of 750 000 to 800 000 t/a. With the present state of the world economy in 2000 the growth rate for the traditional dye industries is likely to be around 3-4%, which represents something like an additional 30 000 t/a. However, the growing high-tech industries such as ink-jet printing are now consuming significant amounts of dyes. Whilst the volumes are lower than for traditional dyes, the specialized nature of these new dyes mean they command much higher prices.

|

Table 1.2 World dye production trends, 103 t

[a] Eastern Europe, former USSR, and China. |

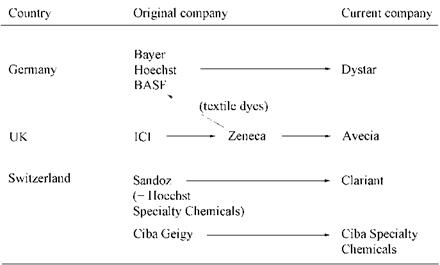

For many years the major European chemical companies remained largely unchanged. Thus, chemical production, including dyes and drugs, were carried out in Germany by Bayer, BASF, and Hoechst; in Switzerland by Ciba-Geigy and Sandoz; and in the UK by ICI. These three countries represented the focus of the world’s dyes (and pigments) production. The last decades have seen massive changes to the chemical industry, including the dyes industry. Companies have undergone major reorganizations, divestments, and acquisitions to focus on “core” activities, particularly life sciences and pharmaceuticals. Consequently, most of the dyes businesses have been divested, with mergers in certain cases. Table 1.3 shows the current situation in Western Europe.

Table 1.4, which shows the global manufacturers of colorants, highlights the growth of indigenous colorant producers in India and particularly the Far East.

|

Table 1.3 Major Western European dye procedures

|

|

Table 1.4 Global manufacturers of dyes.

|

18 августа, 2015

18 августа, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике