Coloration of Plastics

Cerium sulfide pigments have been developed primarily for the coloration of plastics. Shades of existing cerium sulfide pigments vary from light orange to dark red/burgundy. Colors obtained are less chromatic than with cadmium pigments, but are much brighter than with iron oxides.

The use of cerium sulfide in combination with white pigments leads to light salmon to pink shades. Their tinting strength is somewhat weaker than that of cadmium pigments, but is similar to that of lead pigments.

Table 4.3 indicates, for the range of existing cerium sulfide pigments, the typical quantity of pigment necessary to achieve a standard depth of shade of 1/25, when combined with 1% rutile TiO2 pigment.

|

Table 4.3 Tinting strength of cerium sulfide pigments in plastics.

|

Cerium sulfide pigments provide relatively high opacity and hiding power, similar to cadmium and lead-based pigments.

Cerium sulfide pigments can be used either alone or in combination with other pigments and colorants to obtain orange and red shades. They are also successfully employed as shading pigments in pastels and beige tints.

Cerium sulfide pigments can be readily dispersed in a variety of polymeric resin systems using conventional plastics processing equipment. They are both nondusting as well as dispersible (Figure 4.10).

Being inorganic, cerium sulfide pigments are not susceptible to migration when dispersed in a polymer matrix and are not soluble in thermoplastics. They do not cause blooming or bleeding, or show streaking effects during processing. They impart dimensional stability to molded parts because they are free from

Figure 4.10 Image of a polypropylene sample pigmented with cerium sulfide obtained by optical microscopy.

shrinkage or warpage. This is, of course, of prime importance in the coloration of crystalline or semi-crystalline polymers.

shrinkage or warpage. This is, of course, of prime importance in the coloration of crystalline or semi-crystalline polymers.

When combined with other pigments or colorants, cerium sulfide pigments may even improve the dimensional stability of the resulting formulation, for example in high density polyethylene and polypropylene. Use of cerium sulfide pigments can even facilitate processing and allow reduction of cycle times in injection molding machines in comparison to organic based formulations. Cerium sulfide pigments have also only minimal effect on mechanical properties, for example, impact strength.

Besides the fact that they are compatible with most thermoplastics, cerium sulfide pigments can also be used in a wide range of other polymers including engineering plastics, thanks to their very good heat stability.

Table 4.4 gives results of heat resistance tests performed in various thermoplastics at 0.5% pigmentation levels. Samples were obtained by injection molding at increasing temperatures with 5 min dwell time. The temperatures reported correspond to that at which an appreciable color change (DE* of 3) is observed.

|

Table 4.4 Heat stability of cerium sulfide pigments in various polymers.

|

An additional benefit of such high levels of heat resistance is the potential for recycling pigmented material with limited color degradation.

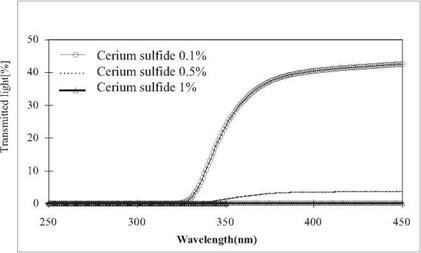

Thanks to their strong UV absorption characteristics, cerium sulfide pigments are not only light-fast (Table 4.5), but can protect the medium in which they are incorporated from deterioration by UV light (Figure 4.11).

|

Table 4.5 Lightfastness of cerium sulfide pigments in various polymers.

|

Hence, cerium sulfide pigments can be used advantageously in very demanding, high light-fastness applications such as automotive interiors.

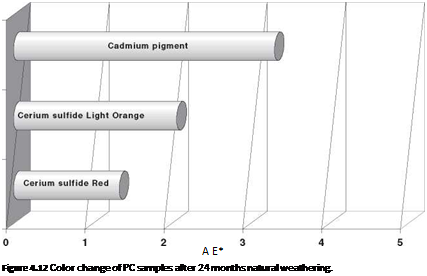

Cerium sulfide pigments show outstanding weathering performance in most thermoplastics, including polyolefins, ABS, PC, PA and PMMA (Figure 4.12). However, cerium sulfide pigments are not recommended for durable PVC application, where discoloration is observed, probably related to the fact that the dehydrochlorination reaction typical for PVC degradation generates free HCl, which could attack cerium sulfide.

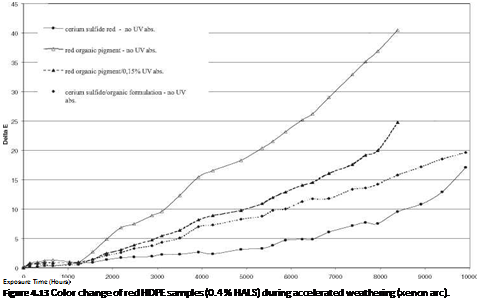

Thanks to their UV screening effect, cerium sulfide pigments can have a beneficial effect on weathering performance in polymer systems. As shown in Figure 4.13, a combination of cerium sulfide pigments with red organic pigments is significantly more stable than the pure organic formulation. Furthermore, the addition ofcerium sulfide pigment tends to allow reduction of traditional UV absorber level.

While pure cerium sulfide is sensitive to acidic species and moisture, its stability can be improved as a result ofsurface treatment.

During processing of polyamide under extreme conditions of temperature and shear in, for example PA6,6 with high levels of glass fiber reinforcement, the chemical stability of existing standard cerium sulfide pigments may be compromised, with some H2S emissions detected. Further developments are in progress to obtain grades with improved stability.

|

|

The possibility of interaction with CuI stabilizer used in polyamide has also been reported as giving rise to unexpectedly darker shades.

Though processing in polymeric resins at moderate temperatures has proved successful, cerium sulfide is not recommended for the coloration of fluoropoly — mers, because of possible reaction and resulting discoloration in the presence of HF formed at high temperatures.

4.4.2

1 сентября, 2015

1 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике