3.4.1

General Points

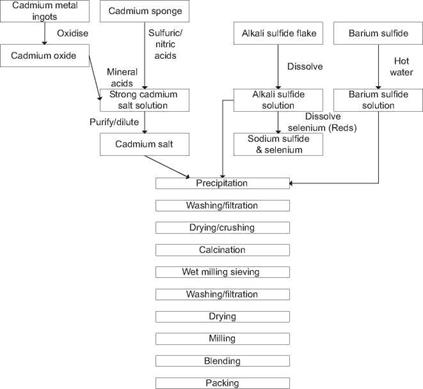

Today’s high-performance pigments require the use of high grade starting materials and a controlled process to ensure the production of consistent colors. Early methods for cadmium pigments would appear crude by modern techniques, and would not be capable of producing the commercially required products of today.

The process route to cadmium pigments is reasonably lengthy, as it includes two filtration and two drying stages, with a significant proportion of the cost of the pigment taken up by the process costs. Today’s manufacturers produce a range of yellows and reds, referred to as “standard bases” or “strike standards”. From this range it is possible to blend the pigments to customer requirements and add extenders as necessary to control color and strength.

Cadmium pigments require to be made from pure grades of chemicals, especially as many common metal sulfides such as iron, nickel, copper and lead are darkly colored and would inhibit pigment brightness and acceptability.

The production oflithopones requires the use ofbarium sulfide, which coprecipitates barium sulfate with the pigment. Lithopone production has declined in recent years, being more expensive than mixing with blanc fixe at the final blending stage. Precipitation is undoubtedly the preferred route to producing today’s high-performance pigments, by providing an intimate mix of the ingredients and achieving close control over particle size.

Cadmium pigment manufacturers have over the years developed ways to improve pigment strength, brightness and dispersibility, and a reduction in the

|

Figure 3.4 Typical production route. |

release of soluble cadmium, but production is generally likely to consist of the following stages:

1. Formation of cadmium oxide (optional).

2. Formation of cadmium sulfate and other solution making.

3. Precipitation and production of the cubic form.

4. Calcination and pigment formation in hexagonal form.

5. Removal of soluble cadmium and production of a fine powder.

Blending and color matching to customer requirements.

A typical production route is illustrated in the process diagram (Figure 3.4).

3.4.2

27 августа, 2015

27 августа, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике