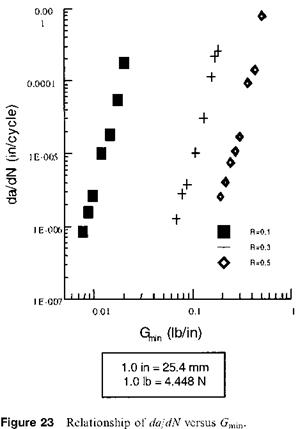

The fatigue behavior of the phenolic FRP-wood interface bond was investigated [7], using a TDCB specimen for constant strain energy release rate range AG. The load ratio effect

|

|

|

|

on interface crack propagation rate at room temperature and laboratory conditions was obtained. A modified Paris Law equation was proposed to explain the load ratio effect. The results of fatigue fracture of FRP-wood interface bonds are summarized as follows:

(1) The TDCB specimen is shown to be suitable for FRP-wood interface fatigue tests. The FRP-wood interface displayed the typical crack propagation behavior under constant cyclic loading as observed by others.

(2) The compliance method used for the TDCB specimen is quite simple, relatively precise, and effective for measuring the crack propagation rate of FRP-wood interfaces.

(3) The Paris Law of Eq. (6) using the strain energy release rate as a controlling parameter can be efficiently applied to a given value of load ratio R.

(4) Considering the minimum strain energy release rate Gmin as a secondary controlling parameter to explain the effects of load ratio R, an equivalent strain energy release rate can be defined as in Eq. (7). In Eq. (7), l is a material constant, which defines the relative importance of the minimum strain energy release rate Gmin and strain energy release rate range AG to the crack growth rate. By a trial and error approach, l is obtained equal to 0.13 for the phenolic FRP-wood interface.

(5)

Finally, the modified Paris Law equation for the phenolic FRP-wood interface considered is given as

The proposed Eq. (9) can efficiently represent the load ratio effect on any propagation rate of phenolic FRP-wood interfaces, and it can further be used for other similar studies of interface fracture of dissimilar materials.

16 июля, 2015

16 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике