West Virginia University, Morgantown, West Virginia, U. S.A.

The University of Akron, Akron, Ohio, U. S.A.

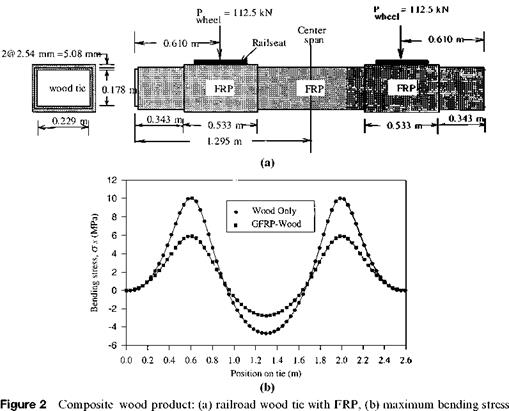

There is a worldwide need to rehabilitate and improve civil infrastructure, and to this end, new construction materials and methods are being intensely investigated to alleviate current problems and provide better and more reliable future structures. To improve performance, service life, and possibly durability of wood structures, fiber-reinforced plastic (FRP) composites are increasingly being used as reinforcement for wood. New FRP-wood hybrid materials for high volume construction applications are being developed from low-cost constituents, such as reconstituted wood composites and synthetic fibers and resins. Current applications of wood reinforcement have focused on the use of FRP strips or fabrics bonded to wood members. Two types of FRP-wood reinforcements are being employed: FRP strips (plates) bonded to wood [1] (used commercially for glulam beams, see Fig. 1) and wood cores wrapped with FRP by filament winding [2,3] [being investigated for reinforcement of railroad wood cross-ties (see Fig. 2) or wood utility poles].

Similar to wood products, the favorable attributes of FRP-wood materials are lightweight, noncorrosive, nonmagnetic, and nonconductive properties. In addition, FRP — wood materials exhibit excellent energy absorption properties, suitable for seismic response; high strength, fatigue life, and durability; competitive costs based on load capacity per unit weight; and ease of handling, transportation, and installation. The potential applications of FRP-wood materials include bridges, railroad ties, poles, long-span roof structures, buildings, highway noise barriers, fire barriers in coal mines, storage structures exposed to salts and chemicals, and many others.

Although significant increases in stiffness and strength have been achieved by this reinforcing technique, there is a concern about the reliable performance of the FRP-wood interface bond, which can be susceptible to delamination. An inadequate interface bond

Bondlines

|

(interfaces)

|

(after Ref. 2). |

strength and integrity can lead to delamination and premature failure of a hybrid FRP — wood composite and degrade the service performance of the product.

In this chapter, an overview of performance characterization of FRP-wood bonded interfaces by conventional and fracture mechanics tests [4-7] is presented. Modified ASTM standard tests (ASTM D2559 and D905) are first used to study the service performance and shear strength of the bond under moisture and/or mechanical loads, and then a contoured or tapered double cantilever beam specimen [8] is used to evaluate the fracture toughness of bonded interfaces under dry and wet conditions and cyclic loading.

Based on the results on performance evaluation, recommendations and guidelines are given for evaluation and qualification of wood-wood and FRP-wood bonded interfaces.

13 июля, 2015

13 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике