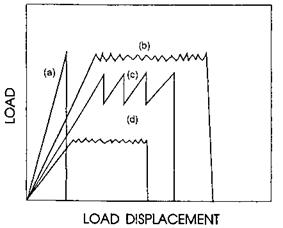

Once it initiates, a crack may propagate in one of several ways. It may fracture completely and catastrophically as glass (unstable) (Fig. 12a), it may fracture in several moderate

|

Figure 12 Characteristic crack growth behavior and fracture toughness of wood adhesive joints: (a) strong/unstable; (b) strong/stable; (c) strong/moderately unstable; (d) weak/stable. |

increments of growth with intermediate arrest points (stable/unstable or stick/slip) (Fig. 12c), or it may fracture by tearing or continuous small increments (stable) (Fig.12b and d). The preferred joint is that which requires a high crack initiation energy and produces stable crack growth (Fig. 12b). Such a joint requires a great amount of energy for complete failure to occur.

Polymers, including adhesives, exhibit these behaviors. As such, an adhesive influences the fracture behavior of the joint in several ways. If the adhesive is formulated, applied, or cured improperly, its cohesive strength and toughness may be lower than that of the wood; if the adhesive does not properly wet or penetrate the wood, the adhesion strength may be lower than the cohesive strength of the wood. Under these circumstances, the crack will travel preferentially in the weaker adhesive layer or joint interface. The crack initiation energy will be low, and crack growth will be stable with little difference between the crack initiation and arrest energies. Such behavior would be expected from a starved or filtered joint or one between inactivated wood surfaces. Similar behavior would be expected from a joint made with adherends whose surfaces have been damaged by crushing during machining or by chemical degradation. In this case the crack travels in the wood or wood interphase but does not deviate far from the plane of the wood surface. The fracture surface produced by this type of crack growth behavior is often termed shallow wood failure. Poor adhesion also produces this type of crack growth behavior and shallow wood failure.

Stable/unstable or stick/slip crack growth occurs when the adhesive is properly formulated, applied, and cured and the grain direction is purposely directed toward the bondline. The adhesive is stronger than the wood and tough to moderately tough. The weak planes in the wood force the crack toward the bondline. Under these conditions, the crack will travel in the wood near the interphase, or in the interphase, and occasionally cross the adhesive layer [42]. The crack initiation energy will be moderately high to high, depending on the plasticity and strength of the adhesive and the species of wood. As the joint is loaded, some energy will be stored in elastic deformation of the adhesive and the adherends, and some will be consumed in plastic deformation and microcracking in the wood surrounding the crack tip. Once crack growth begins, the crack tip will advance and consume the stored energy at a high rate. The crack will arrest when the stored energy level drops below a certain level. Arrest will likely not occur in the adhesive or the interphase but in a region of lower wood density where a large amount of energy is rapidly consumed. The crack tip may remain fixed in this region or grow slowly by microcracking ahead of the primary crack tip, as additional energy is stored in the adhesive and the adherends. The later scenario seems more probable in wood joints, considering the weak interphase between the S1 and S2 layers. Rapid propagation occurs when the stored energy again reaches the critical level. This type of joint is created specifically for testing the fracture toughness of bonded wood joints. It also occurs at random in real joints as a result of the natural grain variation and variation in the plane of cut. The fracture surface resulting from this type of joint and crack growth behavior is typically interphasal or shallow-wood, although somewhat deeper wood failure may occur in low-density regions. It is also typified by occasional to frequent crossings of the adhesive layer from one interphase to the other. These crossings are due to variations of the strength and modulus of the adherends on either side of the adhesive layer. Crossings are facilitated by a precracked (cure-shrinkage cracked) adhesive layer (Fig. 8) or hindered by a continuous tough adhesive layer (Fig. 9).

Stable crack growth also occurs when the adhesive is strong and tough and has established good adhesion, the wood surface is sound, and the grain angle is parallel or away from the bondline. Under these conditions, the crack deviates into the wood according to the mechanisms described by Wang and others [51] and Knauss [52] and remains there. The fracture toughness of the joint is essentially determined by the toughness of the wood. The fracture surface does not necessarily follow the plane of the bondline. It is more likely to follow the grain angle, producing what is often termed deep wood failure. In this type of fracture, the crack advances by continuous transwall cracking of the thin-walled cells and intrawall or diagonal transwall cracking of the thick-walled cells. Stable crack growth will also occur when the adhesive establishes good adhesion but is weaker than the wood, as for example with elastomeric and some thermoplastic adhesives (100% adhesive failure). These adhesives are too weak to store sufficient energy in the adhesive or the adherends to support rapid crack propagation. Instead, the adhesive tears slowly when it reaches its ultimate tensile stress. In testing, this rate is controlled by the rate of crosshead movement. There is essentially no difference between the crack initiation and crack arrest energies.

The brittleness index [53] is a normalization of the energy released during a period of rapid crack growth with respect to the energy stored in the joint just at the onset of crack growth. It provides a quantitative measure of the behavior described here.

J Gc — Ga

Gc

where J is the brittleness index, Gc the energy required to initiate crack growth, and Ga the energy remaining at crack arrest. According to this measurement, an ideally brittle (Fig. 12a) (unstable) material that fails suddenly and completely will have an index (J) value of 1 and an ideally plastic (stable) material that fails by continuous tearing (no difference between initiation and arrest energies) will have an I value of 0. Practically, most wood-adhesive joints fail by a combination of unstable and stable crack growth and have J values between 1 and 0. Joints tending toward stable crack growth (Fig. 12b and d) will have J values in the range 0.8 to 0.95. Joints tending toward more unstable behavior (Fig. 12c) will have J values in the range 0.4 to 0.8.

The stability of crack growth behavior was also quantified by acoustic emissions (AEs) per unit of new surface area formed by crack propagation [41]. Large bursts of AEs occurred during unstable crack growth. Fewer but continuous AEs occurred during stable crack growth. A joint producing 100% bursts of AE during fracture would correspond to a brittleness index of 1 and be perfectly brittle. A joint producing 100% continuous AE would correspond to a brittleness index of 0 and be perfectly plastic. The ratio of burst to continuous AE provides a measure of the stability or instability of the crack growth. The burst to continuous AE ratio of bonded wood joints fell in the range of 0.5 (quite stable) to about 5 (quite brittle). The maximum crack initiation energy tended to be associated with a ratio of about 1.3 times as many burst AEs as continuous AEs.

In the Suzuki and Schniewind study, the fracture toughness of joints made with a variety of conventional, modified conventional, and nonconventional wood adhesives was linearly associated with the AEs per unit area of new crack surface formed during testing. The maximum fracture energy and AEs as a function of various modifications such as filler content, fortifier, and adhesive layer thickness were clearly evident from the relationship. Two different relationships between fracture toughness and AEs were also evident. Nonrigid adhesives, including epoxy, poly(vinyl acetate) (PVA), emulsion polymer isocyanate (EPI), and PVA-modified phenol-formaldehyde (PF), were approximately 2.8 times tougher at a given AE count per unit of area as were conventional rigid thermosetting adhesives, including urea-formaldehyde (UF), PF, phenol-resorcinol formaldehyde (PRF), and isocyanate. The less rigid adhesives absorb or dissipate more energy before cracking than do the rigid adhesives. Viewed another way, for a given level of energy expended to create a new fracture surface, a joint bonded with a rigid adhesive produced approximately 20 times as many acoustic events (microcrack formations) as did a joint bonded with a nonrigid adhesive. Obviously, some of these additional events are in the adhesive, but most are in the wood, given a high percentage of wood failure. In a sense, the less rigid adhesive protects the weak S1-S2 interface by reducing the stress concentration at the crack tip.

12 июля, 2015

12 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике