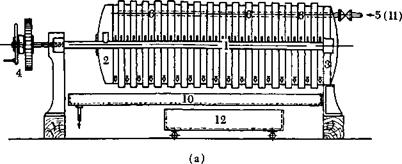

In the laboratory, the dye chemist uses a suction funnel and flask to separate solid materials from liquids. In the plant, however, such equipment is suitable only for filtering coarse precipitates which, even in thick layers, do not offer too much resistance to passage of the liquid. Fine precipitates — and this includes the great majority of dyes — must be filtered through a filter press in large scale operations (see Fig. 56, page 376, and schematic drawing in Fig. 42a-4i).

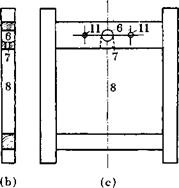

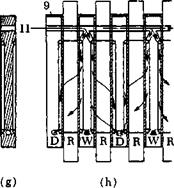

The mixture to be filtered is forced by air pressure out of the pressure chamber (blow-case) (3 in Fig. 56) into the filter press through the feed line (5 in Fig. 42a). The material passes from the entry tube (6) through the holes (7 in Fig. 42b-d) in the filter frames into the hollow spaces (8). The solid material is held back by the filters (9), while the mother liquor passes through the filters and collects in the channels in the filter plates. Thence, the liquid flows down through the holes and stopcocks, and, if it is not to be treated further, through the discharge tube (10). At the beginning of a filtration, only weak pressure is applied until the filter, especially if new, is sealed with the material, and then full pressure (generally several atmospheres) is applied. If the press is full, the mother liquor is emitted slowly, but with a batch of the correct size, it is blown out. The filtered material can be washed if neces-

![]()

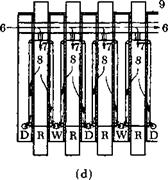

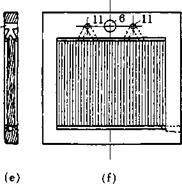

F>g — 42. Filter press: (a) assembled press; (b. c) filter frame, R; (d) filtering;

(e, f) wash plates, W; (g) filter plates, D; (h) washing.

sary. Ibis is done in the empty pressure chamber in the same way as the original filtration, or, in the case of difficultly soluble materials, by introducing water through the two side feed lines (11) in the solid head — piece which lead to the channels in the wash plates (see Fig. 42e-h). The stopcocks in the washing chamber (W) must be closed during washing. When the mother liquor has been removed and the wash water comes through clean, air is blown through the water feed line to dry the press cake. The press is then opened, the product is emptied into the box (12) and the filters are scraped with a wooden spatula.[71] The press is then reassembled and filtration is continued.

If the filtrate is turbid, it is collected and run through again. This should be done early in the filtration. A filter which is torn during the filtration can also be the cause of turbidity in the filtrate. If it is a port of a filter plate which runs turbid, this should be closed. If, however, it is a port of a wash plate, closing it would cause the cloudy liquid to flow back along the route of the wash water and distribute it to all the wash chambers. In the latter case, the turbid filtrate is collected separately and returned to the filter.

A more complete description of the numerous special types of filter presses, and of other industrial filtering equipment, is given in other places.104

28 декабря, 2015

28 декабря, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике