This azo dye component is obtained from p-nitroacetanilide by neutral reduction, using a procedure almost exactly like several that have already been described. In an iron beaker equipped with a stirrer (Fig. 17), a mixture of 250 grams of pulverized cast iron shavings, 15 cc. 40 per cent acetic acid, and 500 cc. water, is boiled vigorously for a few minutes. The moist nitroacetanilide from 1 mole of acetanilide is added in small portions, and stirring and boiling are continued until a drop of the reaction mixture on filter paper appears colorless. Boiling is continued for 10 minutes longer, replacing the water lost by evaporation. The mixture is then cooled to 70°C., and enough soda is added to make the mixture faintly alkaline. The reduction of the p-nitroacetanilide from 93 grams of aniline can easily be completed in 20 minutes. If boiling is continued during the neutralization, or if too much soda is added, the amino — acetanilide may be hydrolyzed. The solution is not freed from iron at 70°, however, and the rest of the metal is precipitated with just the necessary amount of ammonium sulfide (to the point where a drop on filter paper gives no color with alkali sulfide). The mixture is then filtered.

The filtrate is evaporated to 400 cc. over a flame, and the aminoacet — anilide separates in long needles when the concentrated solution is cooled. The yield from 93 grams of aniline is about 75 grams of pure base. The mother liquor, which contains about 15 per cent of impure material, is evaporated further and more product is cr stallized out.

The material thus obtained is sufficiently pure for technical purposes. A completely pure product can be obtained by a second crystallization from 6 parts of water, preferably using decolorizing carbon. The product prepared on a large scale using vacuum evaporation is somewhat more pure.

Hydrolysis of aminoacetanilide yields the widely used p-phenylene — diamine. This material is very easily oxidizable, and therefore, the hydrolysis must be carried out in the absence of air or by boiling with dilute sulfuric acid. p-Phenylenediamine can also be prepared by reduction of p-nitroaniline. It is used chiefly for the production of brown tints by oxidation on the fiber.

Technical Observations. Formanilide, which is less expensive, is used industrially instead of acetanilide in the preparation of p-nitroaniline. The nitration is carried out at a very low temperature (—20°C.) to minimize the formation of the ortho isomer. The by-product, o-nitroaniline, is also recovered; it finds limited use in azo dye manufacture, especially for the preparation of pigment colors (Hansa yellow 5G, lithol fast yellow R). Hydrolysis of mtroformanilide is done with the calculated amount of sodium hydroxide, and formic acid is recovered from the resulting sodium formate. This process was formerly used to supply the large demand for p-nitroaniline. Today it has been largely displaced by the process employing p-nitrochlorobenzene and ammonia (page 92). Economic factors determine which of the two processes is to be preferred.

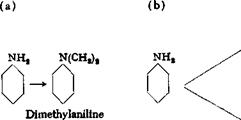

Dimethylaniline (Diethyl — and Ethylbenzylanilines)

|

‘.0

Diethylaniline

The preparation of dimethylaniline is carried out in an iron autoclave withstanding 60 atmospheres of pressure, provided with a cast iron lin — ‘ ing, a manometer and an oil bath. The methyl alcohol used for the alkylation must be free from all traces of acetone and ethyl alcohol, because these compounds, as impurities, cause a very great increase in the pressure. The purity of the methyl alcohol should be established by an iodoform test.

The autoclave is charged with a mixture of 93 grams of pure aniline, 105 grams of pure methyl alcohol, and 9.4 grams of 94 per cent sulfuric acid (66° Вё), and is heated in the oil bath to 200°. The pressure is about 30 atmospheres. The reaction is kept at 215° for 6 hours, then cooled, and 25 grams of 30 per cent sodium hydroxide is added. The autoclave contents are now heated for 5 hours at 170° in order to split the ammonium base sulfates, which are decomposed only at elevated temperatures into sulfuric acid, alcohol, and a tertiary amine. (The formation of quaternary ammonium bases is especially pronounced in the preparation of ethylbenzylaniline and methylbenzylaniline.) The reaction mixture is then steam distilled, and the dimethylaniline is salted out of the aqueous distillate, separated, and distilled through a small bulb column. It is obtained almost chemically pure as a colorless liquid, b. p. 192°, in a yield of about 117 grams.

The purity of the product, which always contains a small amount of monomethylaniline, can be tested by mixing 4 cc. with 2 cc. acetic anhydride. The temperature of the mixture should not increase more than one

degree.

Diethylaniline. The preparation of diethylaniline in the laboratory is equally simple. It must be carried out only in an enameled autoclave, however, because hydrochloric acid is used in place of sulfuric. The latter acid decomposes ethyl alcohol, giving water, ethylene, and carbon.

A mixture of 130 grams of dry aniline hydrochloride and 140 grams of 95 per cent ethyl alcohol is heated for 8 hours at 180°C. in an enameled autoclave. The pressure is about 30 atmospheres. If a stronger autoclave is available, it is advantageous to carry out the reaction at 200°, giving a pressure of 55 atmospheres. The contents of the autoclave are transferred to a glass flask, the alcohol and diethyl ether are distilled off, and the residual mixture of mono — and diethylaniline is treated with 100 grams of 30 per cent sodium hydroxide. The mixture is then stirred vigorously at room temperature with about 40 grams of p-toluenesulfonyl chloride, which converts the monoethylaniline into p-toluenesulfonethylanilide which is not volatile with steam. In this way, the diethylaniline can be obtained completely pure, although an acetic anhydride test for purity should be made, and the treatment with toluenesulfonyl chloride repeated if necessary. The yield is about 120 grams.

The recovered toluenesulfonyl derivative can be hydrolyzed with concentrated sulfuric acid, and the monoethylaniline recovered.

The method above for producing dimethyl — and diethylaniline is not completely satisfactory, but is suitable for small scale work. A cheaper method involves the use of less alcohol and acid, the reaction mixture bang hydrolyzed directly with sodium hydroxide. The monoalkylated base is not separated from the dialkylated compound, but is converted to the alkylbenzyl derivative by means of benzyl chloride. The dialkylaniline and alkylbenzylaniline have boiling points which are far enough apart so that the compounds can easily be separated by vacuum fractional distillation. The following preparation illustrates this procedure.

Ethylbenzylaruline. A mixture of 260 grams of dry aniline hydrochloride and 150 grams of ethyl alcohol is heated in an enameled autoclave for 12 hours at 200°C. The pressure is 21 atmospheres. The mixture is treated as described under diethylaniline, except that it is not treated with p-toluenesulfonyl chloride. The mixture of bases obtained weighs 230 grams; it is practically free from aniline and contains about 38 per cent of diethylaniline and 62 per cent of monoethylaniline.

100 grams of this mixture is placed in a 500-cc. three-necked flask fitted with stirrer, reflux condenser, and dropping funnel, and is mixed with 60 grams of soda which has been moistened with a few drops of water. The well stirred mixture is heated to 50°, and 68 grams of benzyl chloride is added slowly from the dropping funnel. (This is about 5 per cent excess based on the amount of monoethylaniline as determined from the density of the mixture; see table on page 136.) When the addition of the benzyl chloride is completed, the temperature is raised to 100°, and the mixture is stirred at this temperature until the formation of gas bubbles ceases (about 3 hours). It is then poured into water to remove the inorganic salts, and the oil layer is separated and fractionated in vacuum. The» separation is easily accomplished due to the large difference in boiling points. About 38 grams of diethylaniline (complete recovery of the amount present in the original mixture of bases) and about 100 grams of ethylbenzylaniline are obtained.

Mono — and diethylanilines can also be separated by treating the mixture with concentrated hydrochloric acid. The hydrochloride of monoethylaniline crystallizes out and is separated by centrifuging, permitting the recovery of most of the monoethylaniline as such. The residual mixture can be treated with benzyl chloride and soda, as described above, converting it into a mixture of diethylaniline and ethylbenzylaniline.

Technical Observations. Heating of the large autoclaves used in industrial preparations requires from 4 to 6 hours and must be done very carefully. When a temperature of about 190°C. is reached, the pressure increases rapidly from 10 to 30 atmospheres. At the end of the reaction, the excess methyl alcohol, along with the ether formed, is blown out and the vapor is condensed. Splitting of the quaternary ammonium base is carried out in large kettles, using 3000 to 5000 kilograms of dimethylaniline.

Various methods can be used to determine the amounts of monoethylaniline and diethylaniline in a given mixture. One method[26] depends on the determination of the temperature increase occurring when a prescribed amount of the base mixture is mixed with an accurately measured amount of pure acetic anhydride. More reliable and accurate results are obtained, however, by determining the specific gravity of the mixture. From the table below, the composition of the mixture can be determined directly, and with great accuracy, from the density at 15°. It is necessary, of course, that no unchanged aniline be present. This condition is fulfilled in the procedures described above.

The laboratory separation of larger amounts (1 kilogram or more) of mixtures of mono — and diethylanilines can be accomplished relatively easily by fractional distillation, using a column 100 cm. long and 5 cm. wide which is filled with 1-cm. glass Raschig rings. The rings should be supported on a wire gauze with large openings so that the returning liquid is not held up. The column should be insulated to within 10 cm. of the top with asbestos paper. A copper flask is used as the distillation flask, since this gives steady boiling.

The specific gravities (at 15°C.) and boiling points, respectively, of monoethylaniline and diethylaniline are:

Monoethylaniline, 0.9643 at 15°C., 204°С.

Diethylaniline, 0.9389 at 15°C„ 214°C.

The values given in the table below are slightly different from those in the. literature, but they are derived from our own research (G. Widmer).

Per Cent Diethylaniline from the Density of Mixtures of

Monoethylaniline and Diethylaniline at 15°C.

|

Density |

Diethylaniline % |

Density |

Diethylaniline Of /0 |

Density |

Diethylaniline cr О |

|

0.9646 |

0 |

0.9565 |

33.2 |

0.9470 |

70.0 |

|

0.9643 |

1 |

0.9560 |

35.2 |

0.9465 |

71.9 |

|

0.9640 |

2.3 |

0.9555 |

37.2 |

0.9460 |

73.8 |

|

0.9637 |

3.7 |

0.9550 |

39.1 |

0.9455 |

75.6 |

|

0.9634 |

4.8 |

0.9545 |

41.0 |

0,9450 |

77.5 |

|

0.9630 |

6.4 |

0.9540 |

43.0 |

0.9445 |

79.4 |

|

0.9626 |

8.2 |

0.9535 |

45.0 |

0.9440 |

81.3 |

|

0.9622 |

9.8 |

0.9530 |

47.0 |

0.9435 |

83.2 |

|

0.9618 |

11.6 |

0.9525 |

48.9 |

0.9430 |

85.0 |

|

0.9614 |

13.3 |

0.9520 |

50.8 |

0.9425 |

86.7 |

|

0.9610 |

15.0 |

0.9515 |

52.7 |

0.9420 |

88.4 |

|

0.9603 |

17.0 |

0.9510 |

54.7 |

0.9415 |

90.2 |

|

0.9600 |

19.1 |

0.9505 |

56.7 |

0.9510 |

92.1 |

|

0.9595 |

21.2 |

0.9500 |

58.6 |

0.9405 |

93.9 |

|

0.9590 |

23.3 |

0.9495 |

60.4 |

0.9400 |

95.6 |

|

0.9585 |

25.3 |

0.9490 |

62.3 |

0.9395 |

97.4 |

|

0.9580 |

27.3 |

0.9485 |

64.2 |

0.9390 |

99.2 |

|

0.9575 |

29.2 |

0.9480 |

66.1 |

0.93875 |

100.0 |

|

0.9570 |

31.2 |

0.9475 |

68.0 |

26 сентября, 2015

26 сентября, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике