|

|

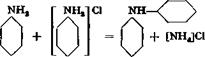

In an enameled autoclave having an enameled thermometer tube, 93 grams of aniline and 93 grams of aniline hydrochloride are heated for 20 hours at 230°C. The pressure rises to about 6 atmospheres. If there is no enameled thermometer tube, the pressure is brought to this point, and the temperature of the oil bath is taken as about 25° higher than the effective internal temperature. After 2 hours, the water vapor present is carefully blown out through the valve, since the reaction is adversely affected by even traces of water. The blowing out operation is repeated three times during the course of an hour — some aniline and ammonia also escaping. There is no advantage in heating longer than 20 hours, and in fact, the yield may even be lowered. After cooling the autoclave, its contents are transferred to a porcelain dish and treated with 1 liter of

|

water. The mixture is heated to 80°, and 30 per cent hydrochloric acid is added until an acid reaction to Congo red is obtained. After cooling overnight, the crude diphenylamine has separated as a solid mass which is easily separated from the mother liquor, since diphenylamine does not

urn

urn

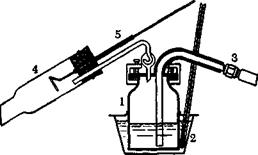

(b) Laboratory distillation vessel for distilling with superheated steam: 1, copper kettle; 2, oil bath with thermometer;

3, connection to superheater; 4, condenser; 5, push-out device.

form a salt with dilute hydrochloric acid. After filtering, the product is again melted with water, leached out with a little acid, and then washed with dilute soda solution. The diphenylamine obtained in this way is extremely impure.

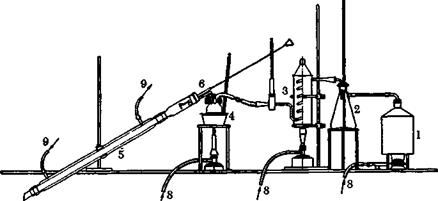

The product must be purified by distillation with superheated steam. For this purpose, it is placed in a distillation flask of about 500 cc. capacity, and an apparatus such as that shown in Figure 23 is assembled.

The ofl bath is heated to 250°, and the superheater is heated with an ordinary Fletcher burner. The steam must be dried carefully and its temperature should be about 300°. If the distillation is carried out well, 1 part of base can be distilled with 2 parts of water. The diphenylamine is obtained as a colorless liquid which solidifies to a light yellow cake. It is obtained completely pure by pouring off the water. The yield of product melting at 51° is about 100 grams. About 35 grams of aniline can be recovered from the acidic mother liquors.

Technical Observations. Not only the autoclave proper, but also the cover, must be enameled. Traces of iron or copper reduce the yield of diphenylamine by as much as 30 to 50 per cent, and cause resinification. The hydrochloric acid extraction is carried out in wooden vats and the distillation with superheated steam is done in apparatus such as that shown in Figure 24. Modem devices are available for producing the superheated steam. It is possible to carry over nearly one part of diphenylamine with one part of water at 230°.

2 октября, 2015

2 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике