The term electrophotography encompasses the familiar techniques of photocopying and laser printing. In these printing systems, the ink is a toner, which is generally a powder consisting mainly of pigment, charge control agent, and a low melting binder. Toner printing systems use optical or electrical methods to form an electrostatic latent image to which the toner is attracted and subsequently transferred to the substrate.

Most photocopiers and laser printers operate on a similar basis, so that it is convenient to discuss them together, but there are also some key differences.

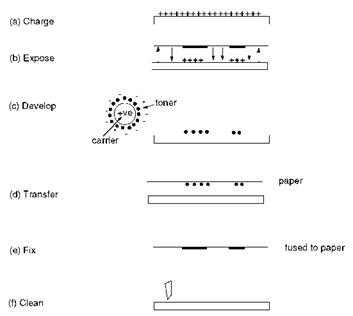

The photocopying process, as illustrated in Figure 10.10, may essentially be separated into six stages. One of the key aspects of photocopying is a photoconducting material which, as the name implies, is a conductor of electricity in the presence of light but an insulator in the dark. In the first stage of the process, the dark photoconducting surface of a drum is given a uniform electrical charge. In the imaging step, the document to be copied is illuminated with white light. Where there is no print, light is reflected on to the photoconducting surface and this causes the charge to be dissipated. Where there is text, light is absorbed and does not reach the photoconductor. In this way, a latent electrostatic image is formed on the drum. The drum is then exposed to toner particles, which have been given an opposite charge to that on the drum. The toner particles are thus attracted to the image areas of the photoconducting surface. The next step involves transfer of the image from the drum to the substrate, usually plain paper, by applying to the back of the paper an electrical potential of opposite charge to that of the toner particles. The next step fixes the image to the paper. This is achieved by a heat treatment, which melts the toner resin and fuses it to the paper. Finally, the photoconducting surface is cleaned to make it ready for the next copying cycle.

|

Figure 10.10 The photocopying process |

In a laser printer, the first step also involves giving the photoconducting drum a uniform electric charge. However, in the second step a laser is used to write on the charged drum the information stored in the memory of the printer. In contrast to the photocopying process, therefore, the charge is dissipated in the image areas. In this case, the toner used carries a charge which is the same as that on the drum, so that it is repelled from the non-image areas on to the uncharged image areas. From this stage onwards, the principles of the laser printing process are similar to the photocopying process.

Organic colorants of a variety of types are key components in the operation of photocopiers and laser printers. The photoconducting drum contains two surface layers. The first is a thin charge-generating layer which is on top of a thicker charge-transport layer. The charge-generating layer contains a charge-generating material which is usually a highly — purified pigment, commonly of the perylene, polycyclic anthraquinone or phthalocyanine type, with carefully controlled crystallinity and particle size. Light interacts with the pigment to form an ion-pair complex at the same time releasing an electron which passes to earth. A positive hole is thus generated which migrates to the interface with the charge-transport layer. This layer contains highly electron-rich compounds, such as poly — arylamines, not usually coloured materials, which facilitate transfer of the positive holes to the outer surface. The toners used in photocopying and laser printers are powders which consist mainly of pigments, charge control agents and resin, a relatively low melting (60-70 °C) polymer. The most commonly used pigment is carbon black since most printing remains monochrome. However, the production of multicoloured prints by this method using pigments of the three subtractive primary colours, yellow, magenta and cyan is increasing in popularity. The yellows are commonly provided by disazo pigments, the magenta by quinacridones and the cyan by copper phthalocyanine (see Chapter 9 for a description of the chemical structures of these types of pigments). Charge control agents are materials which, as the name implies, assist in the control of the electrostatic charge applied during the printing process. These are ionic materials (either anionic or cationic) which may be coloured. For example, 2:1 chromium complexes of azo dyes, similar to those used as anionic premetallised dyes for application to wool (see Chapter 7) are commonly used in black toners.

13 января, 2016

13 января, 2016  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике