6.4.1.1. Background

In 1954, the National Cash Register Company introduced a new copying system, i. e., carbonless copying paper, by which multiple copies were realized without using traditional carbon paper. Since then, there have been numerous changes and improvements, though the original system is still the technological basis for the current carbonless copying papers.

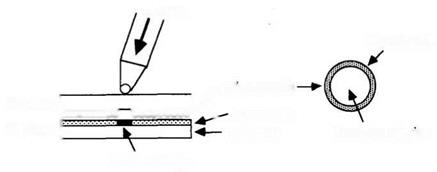

Figure 6.6. Structure of carbonless copying paper.

Carbonless copying paper basically consists of a two-sheet system; the top and bottom sheet are termed the CB and CF sheet, respectively. A cross-sectional view of the structure is shown in Figure 6.6.

The CB sheet is coated on the back with microcapsules 5 to 10 pm in diameter, in which leuco dye solution in a nonvolatile solvent is contained. The CF sheet is coated on the front with an acidic coreactant such as reactive clay, zinc salt of salicylic acid derivatives, zinc-modified phenolic resin, etc. On the application of pressure, the microcapsule is ruptured in the area delineated by the pressure pattern, and the leuco dye solution is thereby transferred to the CB sheet to bring about a color-forming reaction with acidic coreactant resulting in a distinct image on the surface of the CF sheet. By inserting a middle sheet (or sheets) called the CFB sheet, which is coated on the front and back with acidic coreactant and microcapsules, respectively, multiple copies can be obtained.

Today, the total consumption of carbonless copying paper worldwide is estimated to be 2 million tons. The major use for carbonless copying paper is in continuous business forms processed by computer.

6 сентября, 2015

6 сентября, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике